Industry knowledge

Linen is a natural fiber that comes from the stem of the flax plant. The structure of linen is characterized by its long, smooth fibers that have a high tensile strength and durability. The structure of linen fibers is similar to other natural plant fibers such as cotton and jute, but with some distinct differences.

Linen fibers are made up of a number of layers, including the epidermis, fiber layer, and central core. The epidermis is the outermost layer of the fiber and contains wax, which helps to protect the fiber from damage. The fiber layer is the middle layer of the fiber and is made up of cellulose. This layer is responsible for providing the fiber with its strength and durability. The central core is the innermost layer of the fiber and is made up of lignin, which gives the fiber its stiffness.

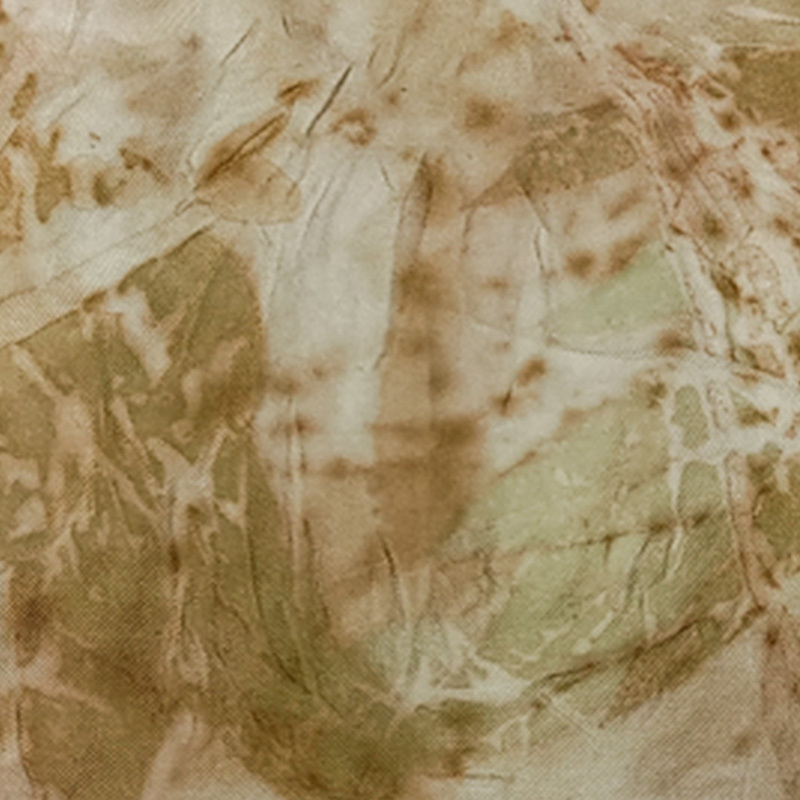

The structure of linen fibers is also characterized by their irregular shape. Unlike synthetic fibers, which have a uniform shape and size, linen fibers can vary in size and shape, which gives them a natural texture and irregularity. This texture is further enhanced by the presence of small bumps and nodes along the length of the fiber.

When spun into yarn, the irregularity of the linen fibers gives the resulting fabric a unique texture and drape. Linen fabrics are often characterized by their crispness and stiffness, which can soften over time with wear and washing. Overall, the structure of linen fibers contributes to the unique properties of linen fabrics, including their strength, durability, and natural texture.

The production steps of Natural fiber Linen

Linen is a natural fiber that is made from the stalks of the flax plant. The production of linen involves several steps, which include:

Retting: The first step in the production of linen is retting, which involves soaking the flax plants in water to soften the fibers and separate them from the woody stem. There are two methods of retting: water retting and dew retting. Water retting involves submerging the flax plants in water for several days or weeks, while dew retting involves leaving the flax plants in the fields to be exposed to dew and rain for several weeks.

Breaking: After retting, the flax plants are dried and then broken to separate the fibers from the woody stem. This can be done by hand or by using a machine called a flax breaker.

Scutching: The next step in the production of linen is scutching, which involves removing the shorter fibers and impurities from the long flax fibers. This is done by using a wooden tool called a scutching knife, which scrapes away the unwanted fibers.

Hackling: After scutching, the long flax fibers are hackled to remove any remaining impurities and to straighten the fibers. Hackling involves combing the fibers through a series of metal combs with progressively finer teeth.

Spinning: Once the flax fibers have been hackled, they are spun into yarn using a spinning wheel or other spinning equipment. The resulting yarn can be used to make linen fabric or other linen products.

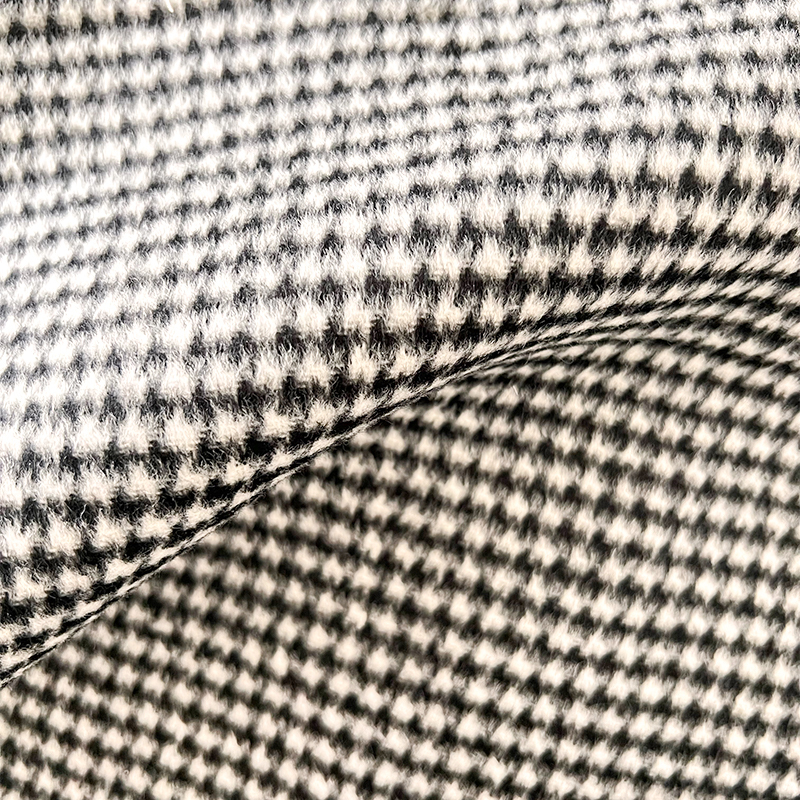

Weaving: The final step in the production of linen is weaving, which involves interlacing the linen yarn to create a fabric. Linen fabric can be used for a variety of applications, including clothing, home decor, and industrial products.

Overall, the production of linen is a labor-intensive process that involves several steps. However, linen is a durable and high-quality natural fiber that is valued for its strength, moisture-wicking properties, and natural luster.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano