Advancements and Innovations in Sustainable Fabric Technologies: A Multidisciplinary Perspective

The textile industry’s ecological footprint has catalyzed a paradigm shift toward sustainable fabric development, driven by interdisciplinary innovations in material science, biotechnology, and circular economy frameworks. Beyond conventional organic cotton or recycled polyester, cutting-edge research is redefining the boundaries of eco-conscious textiles through biofabrication, closed-loop systems, and hyper-functional materials. This article examines the scientific, industrial, and regulatory complexities shaping the next generation of sustainable fabrics.

Content

- 1 1. Bioengineered and Cellulose-Based Fibers: Beyond Plant-Derived Solutions

- 2 2. Chemical Recycling and Polymer Upcycling: Closing the Synthetic Loop

- 3 3. Regenerative Agriculture and Blockchain-Enabled Traceability

- 4 4. Challenges in Commercialization and Policy Frameworks

- 5 5. Future Trajectories: From Biofabrication to AI-Driven Design

1. Bioengineered and Cellulose-Based Fibers: Beyond Plant-Derived Solutions

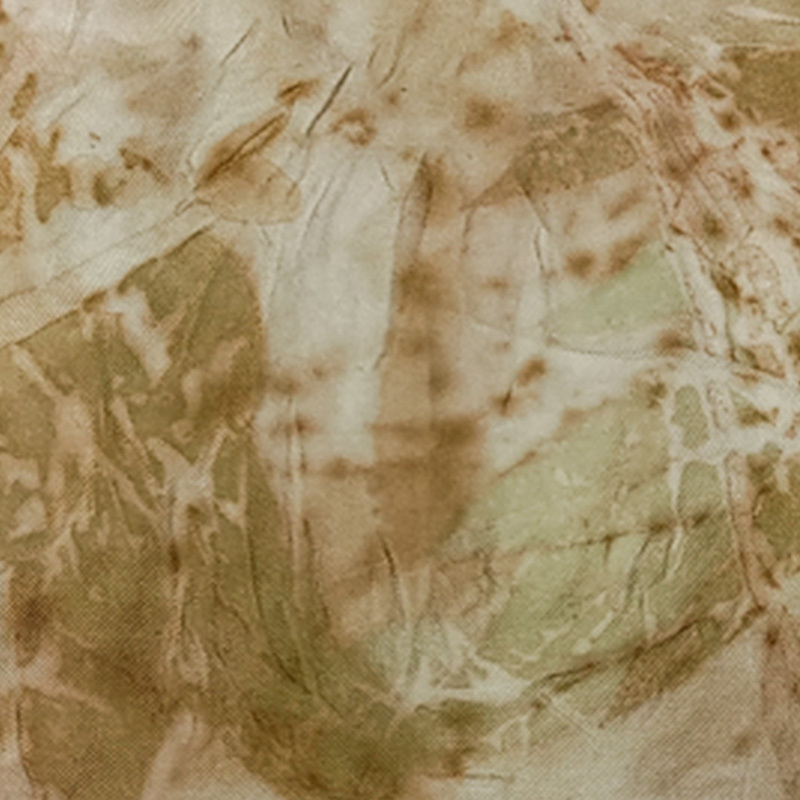

While plant-based fibers like hemp and linen remain staples, novel cellulose sources are emerging to reduce agricultural land use. Mycelium leather, produced by fermenting fungal networks, offers a carbon-negative alternative to animal hides, with companies like Bolt Threads scaling production for luxury markets. Similarly, algae-based textiles—spun from biopolymers extracted from seaweed or microalgae—exhibit rapid biodegradability and carbon sequestration potential. Brands such as Algaeing and Vollebak are commercializing algae yarns that require no freshwater or pesticides.

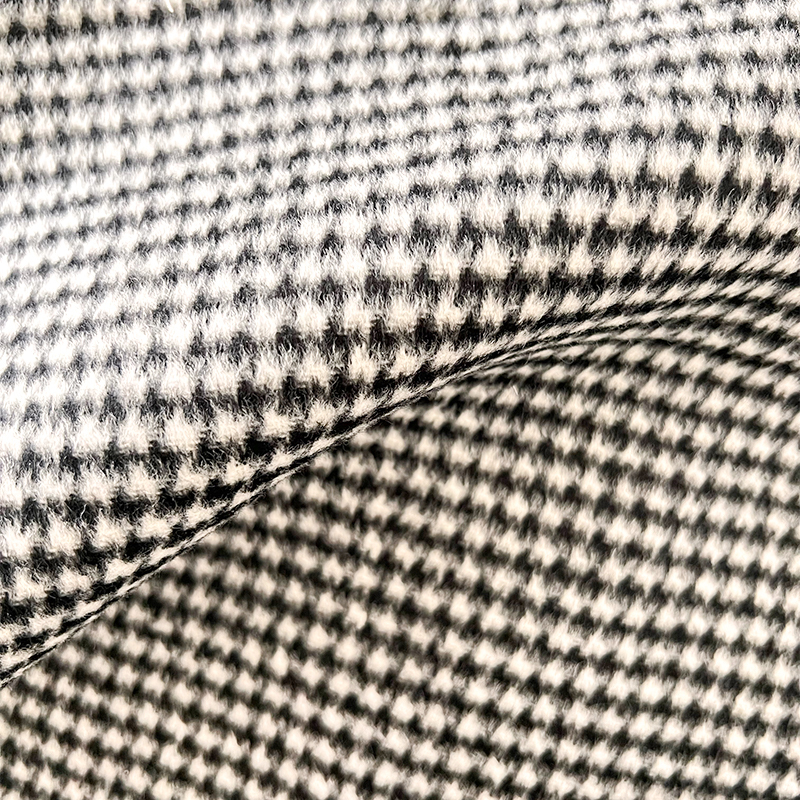

Concurrently, lab-grown cellulose via bacterial fermentation (e.g., bacterial nanocellulose) is gaining traction. Startups like Nanollose convert agricultural waste into microbial cellulose, bypassing traditional pulping processes that contribute to deforestation. These innovations challenge the dominance of cotton, which still accounts for 24% of global pesticide use despite occupying just 2.5% of farmland.

2. Chemical Recycling and Polymer Upcycling: Closing the Synthetic Loop

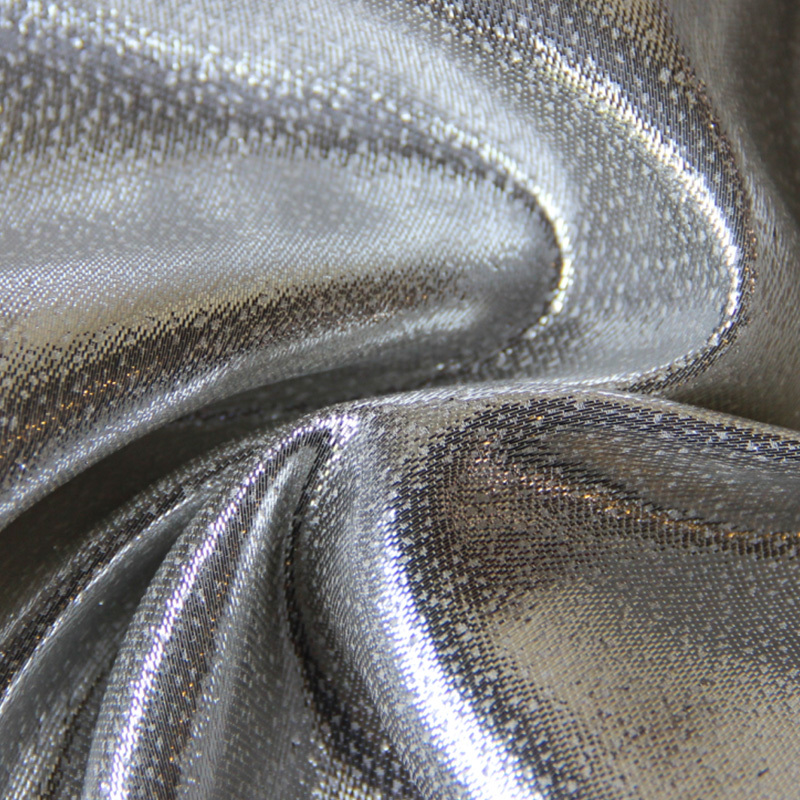

The limitations of mechanical recycling—fiber shortening, blended fabric incompatibility—have spurred advances in chemical depolymerization. Enzymatic recycling, pioneered by Carbios, employs engineered enzymes to break down PET into virgin-grade monomers, achieving 97% purity. This technology addresses polyester’s 60 million-ton annual production volume, of which less than 15% is currently recycled.

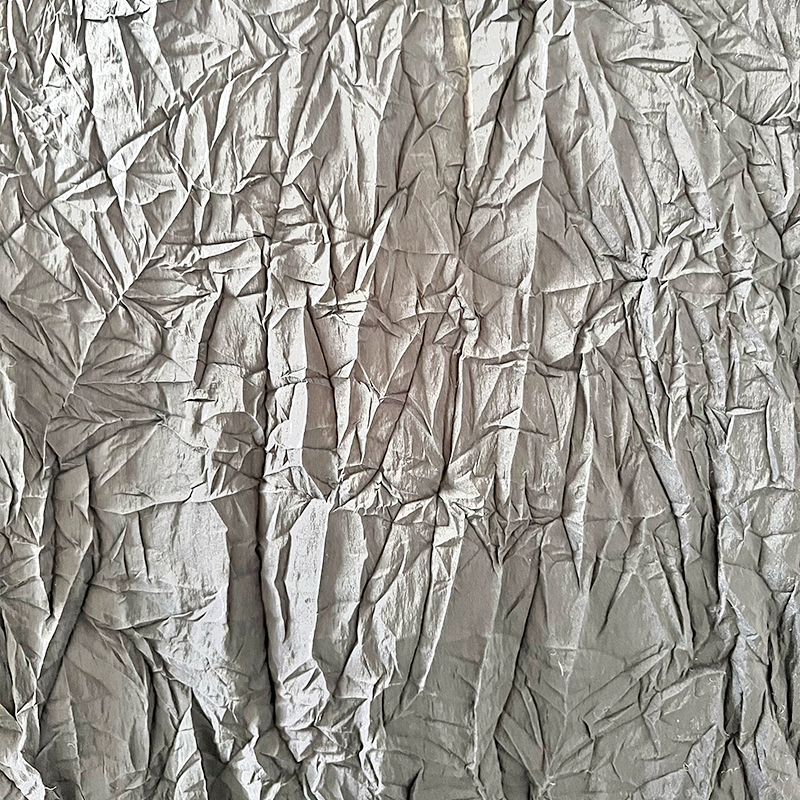

Polyamide 6 (nylon) is similarly being targeted through projects like the European MultiCycle Initiative, which uses supercritical fluids to separate elastane blends. Meanwhile, carbon capture textiles are entering the fray: LanzaTech transforms industrial emissions into ethanol, subsequently polymerized into polyester by partners like Inditex. Such approaches align with the EU’s Single-Use Plastics Directive, which mandates synthetic textile accountability.

3. Regenerative Agriculture and Blockchain-Enabled Traceability

Sustainability extends beyond material composition to encompass cultivation practices. Regenerative organic certification (ROC), endorsed by Patagonia and Eileen Fisher, ensures soil health restoration through crop rotation and no-till farming. However, scalability remains hindered by yield gaps and certification costs averaging 50,000 per farm.

Blockchain solutions are mitigating greenwashing risks. The TextileGenesis platform, integrated with LWG-certified tanneries, maps fiber journeys using cryptographic tokens, ensuring compliance with the EU’s Digital Product Passport regulations. This transparency is critical as 68% of consumers distrust vague sustainability claims (McKinsey, 2023).

4. Challenges in Commercialization and Policy Frameworks

Despite breakthroughs, barriers persist:

-

Cost parity: Mycelium leather remains 2–3x more expensive than bovine leather due to bioreactor energy demands.

-

Regulatory fragmentation: The absence of global standards for “biodegradable” or “circular” claims leads to market confusion. The U.S. FTC Green Guides, last updated in 2012, lack specificity for novel biomaterials.

-

Infrastructure gaps: Less than 1% of post-consumer textiles are recycled into new garments, partly due to limited sorting facilities capable of handling multi-material garments.

Policy interventions are emerging. France’s AGEC Law mandates corporate due diligence on microfiber pollution, while California’s SB 707 targets polyester’s 35% share of microplastic emissions. The Textile Exchange’s 2030 Recycled Polyester Challenge aims to boost uptake to 45%, contingent on cross-industry precompetitive collaborations.

5. Future Trajectories: From Biofabrication to AI-Driven Design

Synthetic biology is poised to disrupt traditional value chains. Engineered Corynebacterium glutamicum strains now produce spider silk proteins for high-tenacity fibers (AMSilk), while CRISPR-edited cotton plants (Texas A&M) yield longer, stronger staples with reduced water needs.

Concurrently, AI tools like Google’s DeepMind are predicting enzyme structures for efficient plastic degradation, and generative design algorithms (e.g., Autodesk’s Fusion 360) optimize fabric patterns to minimize waste. The integration of life-cycle assessment (LCA) databases into CAD software enables real-time sustainability metrics during prototyping.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post