Industry knowledge

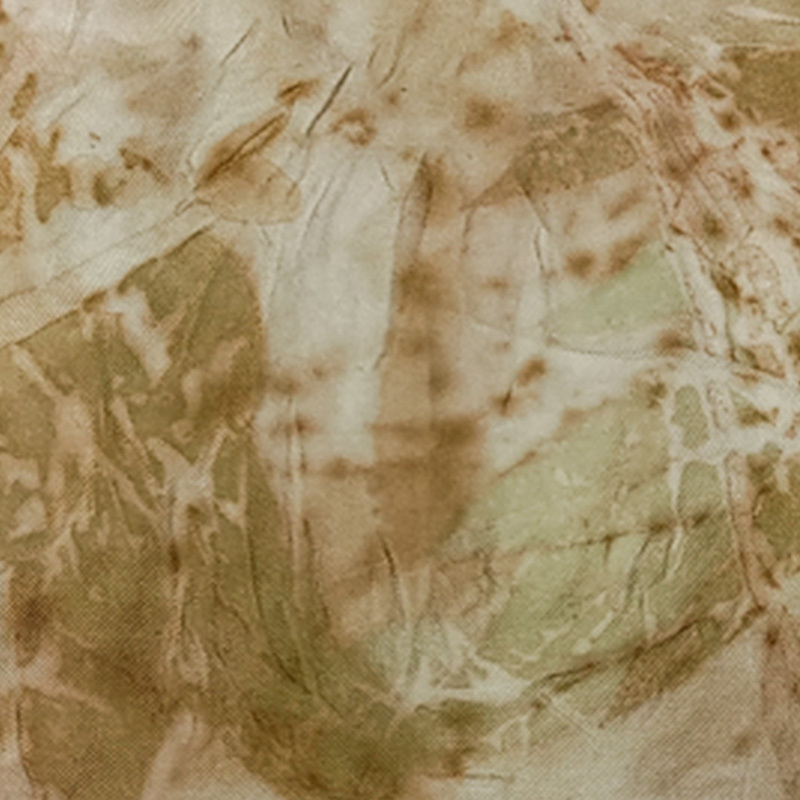

Tie-dye is a fabric dyeing technique that involves twisting, folding, or crumpling fabric and then binding it with string or rubber bands before dyeing it. This creates unique and colorful patterns on the fabric. Here are some tips on how to choose tie-dye fabric:

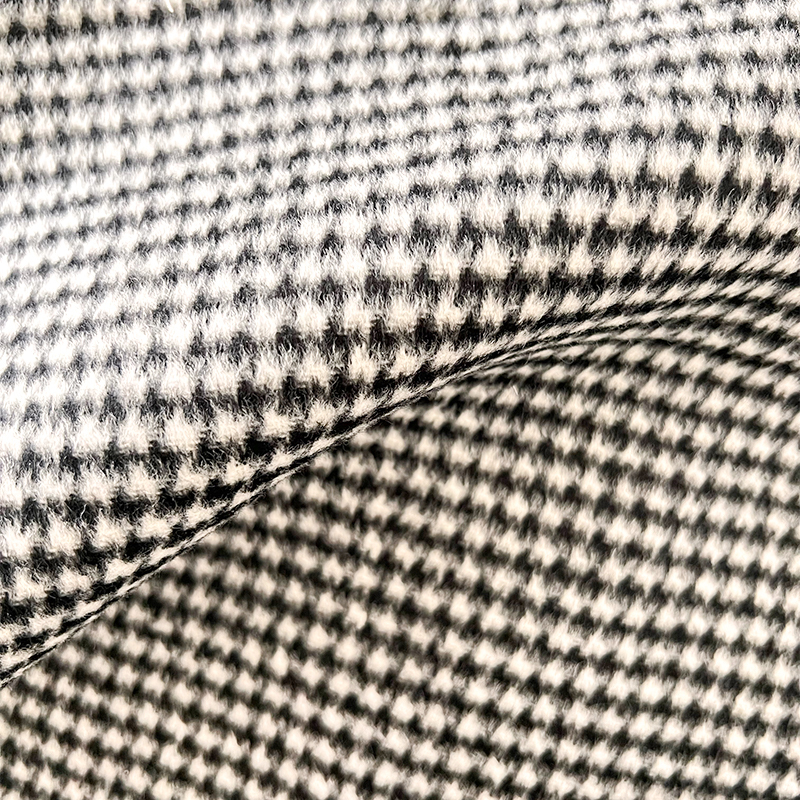

Consider the base fabric: Tie-dye can be applied to a variety of fabrics, including cotton, rayon, silk, and polyester. Consider the properties of the base fabric, such as its texture, weight, and durability, to ensure that it meets your needs.

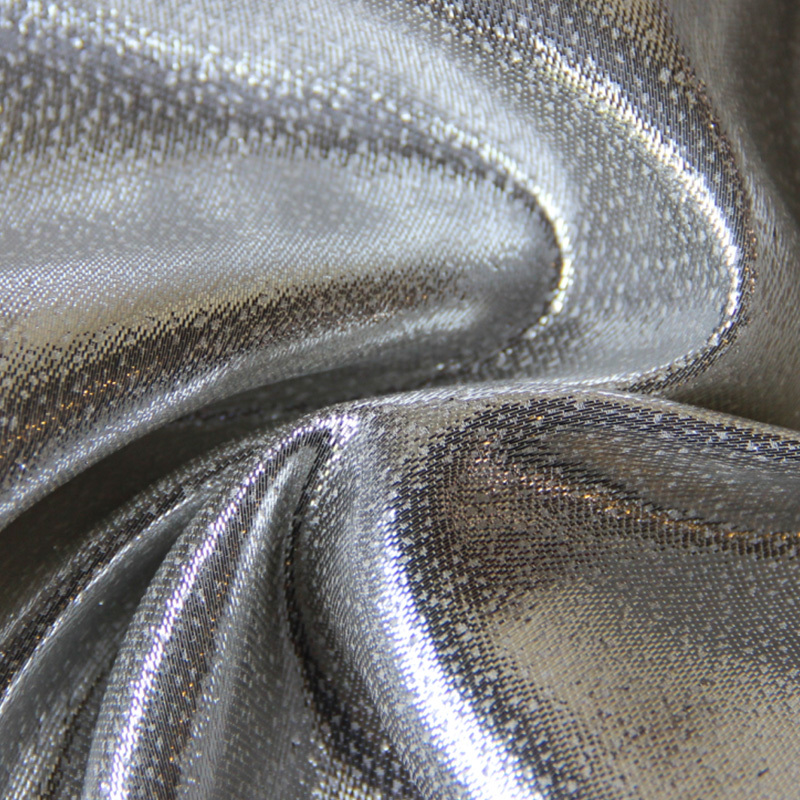

Look for high-quality dyeing: The quality of the dyeing process can affect the final appearance and durability of the tie-dye fabric. Look for fabrics that have been dyed with high-quality dyes that are colorfast and resistant to fading.

Choose the pattern and color scheme: Tie-dye fabrics come in a variety of patterns and color schemes, from bold and bright to subtle and muted. Consider the intended use of the fabric and choose a pattern and color scheme that complements your project.

Check for consistency: Tie-dye patterns can be inconsistent due to the manual nature of the dyeing process. Check for consistency in the pattern and color distribution to ensure that the fabric is of high quality.

Consider the manufacturer: Choose tie-dye fabric from a reputable manufacturer with a history of producing high-quality fabrics. This can ensure that you are getting a product that meets your expectations and will last for a long time.

Overall, choosing tie-dye fabric involves considering the base fabric, the quality of the dyeing process, the pattern and color scheme, consistency in the pattern, and the reputation of the manufacturer. By considering these factors, you can select tie-dye fabric that is perfect for your project.

The production steps of Tie-dye fabric

Tie-dye fabric is a popular fabric dyeing technique that involves twisting, folding, or crumpling fabric and then binding it with string or rubber bands before dyeing it. Here are the general production steps for tie-dye fabric:

Preparing the fabric: The fabric is first washed to remove any dirt or impurities. It is then soaked in a solution of soda ash and warm water to help the dye adhere to the fabric.

Preparing the dye: The dye is mixed with water according to the manufacturer's instructions. The dye may also be mixed with other chemicals to enhance its colorfastness and durability.

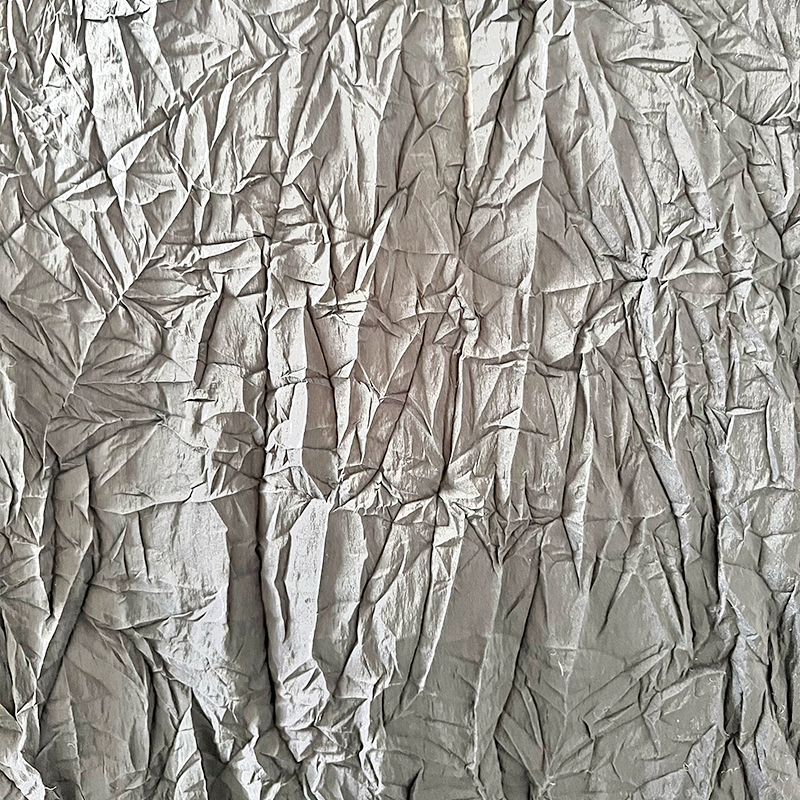

Creating the design: The fabric is then manipulated into the desired pattern by folding, twisting, or crumpling it and securing it with rubber bands or string. The tighter the fabric is bound, the more defined the resulting pattern will be.

Applying the dye: The fabric is then immersed in the dye solution, making sure that all areas of the fabric are covered with dye. The fabric is left in the dye for a period of time, depending on the desired intensity of the color.

Rinsing and washing: After the fabric has been dyed, it is rinsed in cold water to remove any excess dye. The fabric is then washed in warm water with a mild detergent to remove any remaining impurities and ensure that the dye is properly set.

Drying: The fabric is then air-dried or machine-dried, depending on the fabric's properties.

Finishing: Once the fabric is dry, any remaining rubber bands or string are removed. The fabric is then ironed to remove any wrinkles and give it a finished look.

Overall, the production steps for tie-dye fabric involve preparing the fabric, preparing the dye, creating the design, applying the dye, rinsing and washing the fabric, drying it, and finishing it. These steps can be repeated to create additional layers of color and patterns.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano