Industry knowledge

The Structure of tencel fabric

Tencel is a type of fiber made from the wood pulp of eucalyptus trees.

Tencel fabric has a unique structure that contributes to its softness, durability, and other properties. The structure of Tencel fabric can be described as follows:

Fiber structure: Tencel fibers are long, continuous filaments that are spun into yarns and then woven into fabrics. The fibers have a smooth surface and a round cross-section, which contributes to the softness and drape of Tencel fabrics.

Hydrophilic properties: Tencel fibers have hydrophilic properties, which means they are able to absorb and release moisture more efficiently than other fibers. This makes Tencel fabrics more breathable and comfortable to wear in warm weather.

Internal structure: Tencel fibers have a unique internal structure that includes a series of sub-microscopic fibrils. These fibrils are arranged in a way that creates a network of channels within the fiber, which helps to absorb moisture and promote airflow.

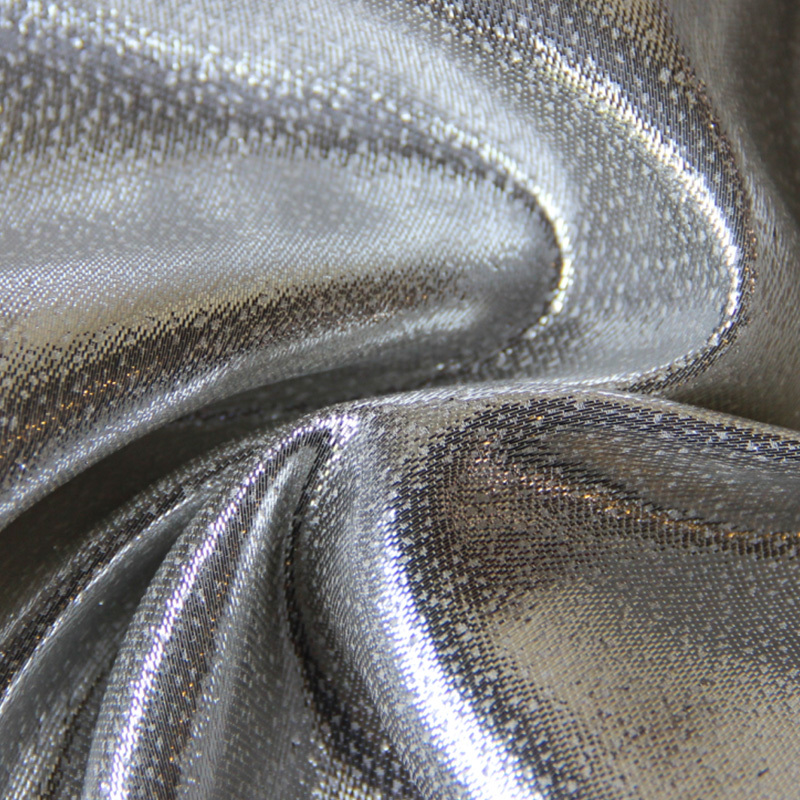

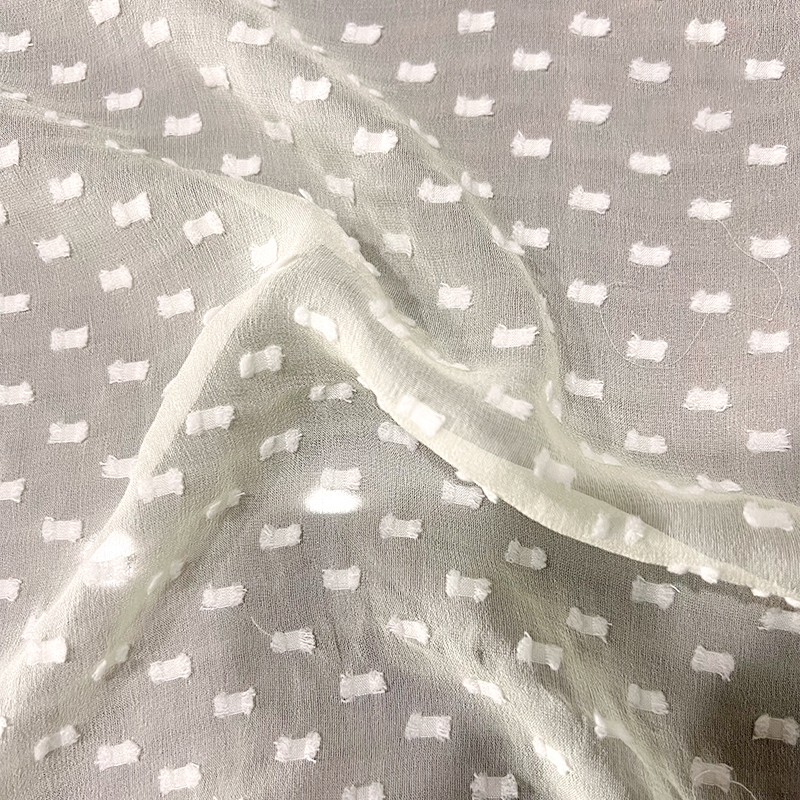

Fabric structure: Tencel fabrics can be woven or knitted, and the structure of the fabric can affect its properties. Woven Tencel fabrics have a tight, smooth surface that enhances their luster and draping qualities, while knitted Tencel fabrics are stretchier and more comfortable to wear.

Overall, the structure of Tencel fabric is optimized to provide softness, durability, and moisture management properties that make it a popular choice for a variety of applications, including clothing, bedding, and home textiles.

The Classification of tencel fabric

Tencel fabric can be classified based on its weave, weight, and finish. Here are some common classifications:

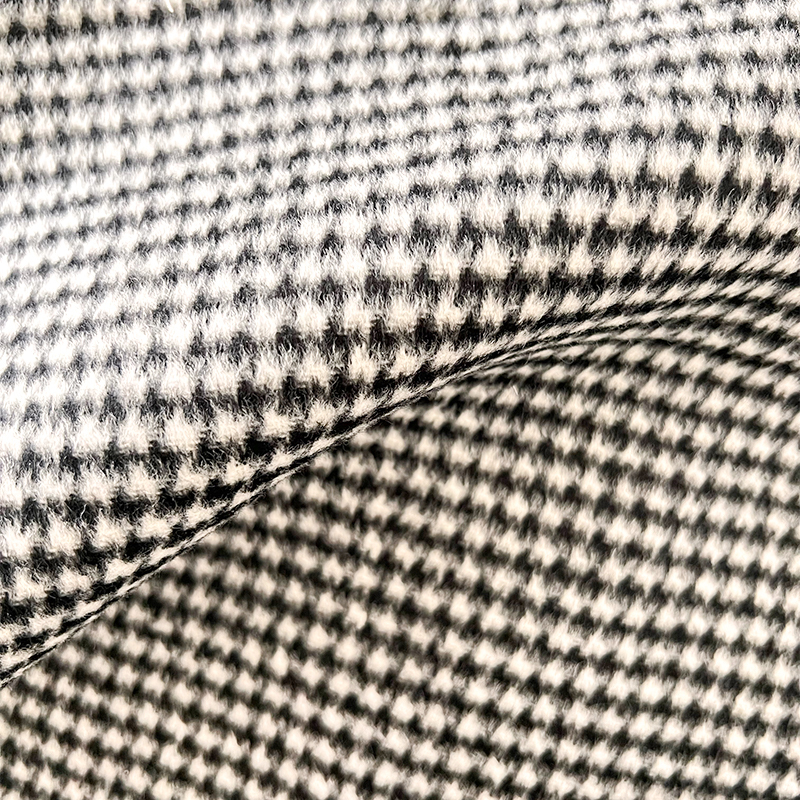

Weave: Tencel fabric can be woven in a variety of ways, including plain weave, twill weave, and satin weave. Plain weave Tencel fabric is the most common and has a simple over-under pattern that creates a durable and smooth fabric. Twill weave Tencel fabric has a diagonal pattern that makes it stronger and more durable than plain weave. Satin weave Tencel fabric has a smooth and shiny surface due to the way the yarns are interlaced.

Weight: Tencel fabric can be made in a range of weights, from lightweight fabrics for summer clothing to heavier fabrics for winter clothing. The weight of Tencel fabric is determined by the thickness of the yarns and the density of the weave.

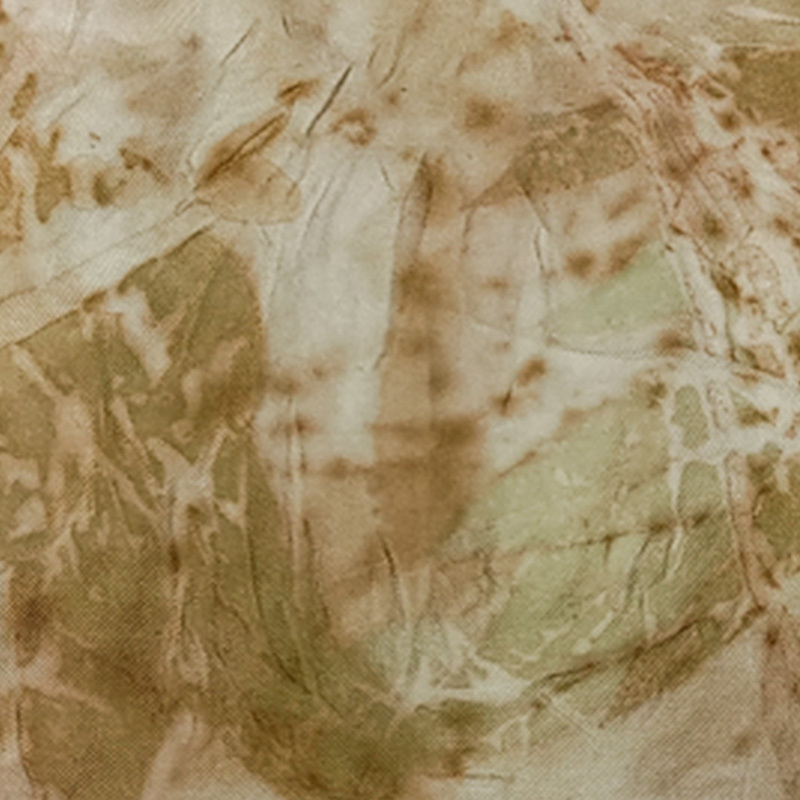

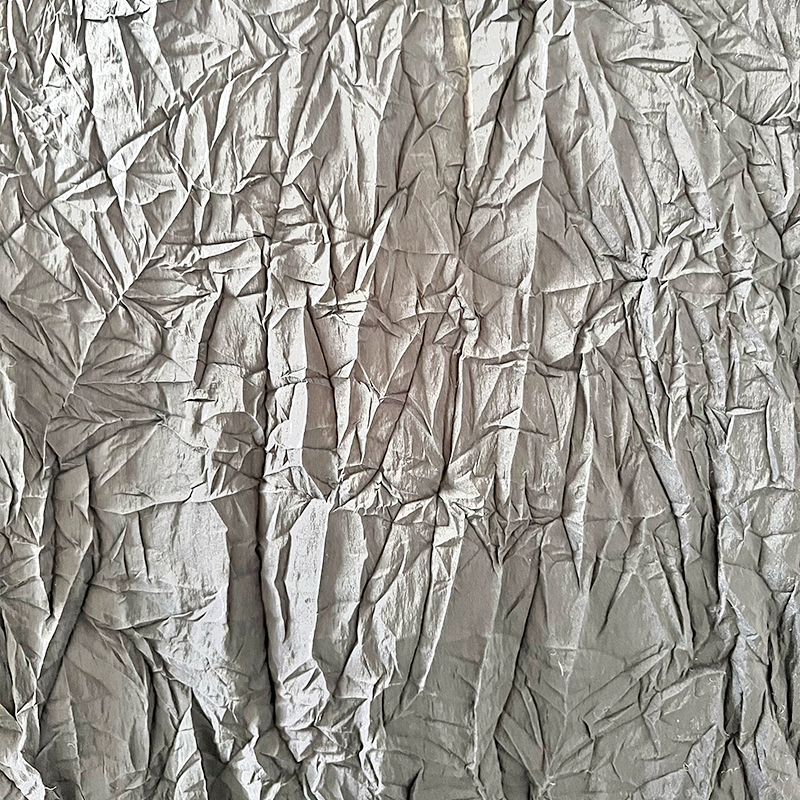

Finish: Tencel fabric can be finished in a variety of ways to enhance its properties. For example, Tencel fabric can be treated with a wrinkle-resistant finish to reduce wrinkles and improve its drape. Tencel fabric can also be treated with a water-repellent finish to make it more resistant to moisture.

Blend: Tencel fabric can also be blended with other fibers, such as cotton or wool, to enhance its properties. For example, Tencel/cotton blends are soft and breathable, while Tencel/wool blends are warm and durable.

Overall, the classification of Tencel fabric depends on the specific characteristics of the fabric, such as its weave, weight, finish, and blend. These characteristics can influence the performance and suitability of the fabric for different applications.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano