Practical Guide to Natural Dye Fabric — Materials, Process & Care

Content

- 1 1. Why choose natural dye fabric?

- 2 2. Which fabrics take natural dyes best?

- 3 3. Preparing fabric: scouring and mordanting

- 4 4. Extracting natural dyes and building a recipe

- 5 5. Step-by-step natural dyeing process (practical)

- 6 6. Aftercare and washing instructions for natural dye fabric

- 7 7. Troubleshooting common issues

- 8 8. Sustainable practices and safety notes

- 9 9. Quick reference: dos and don'ts

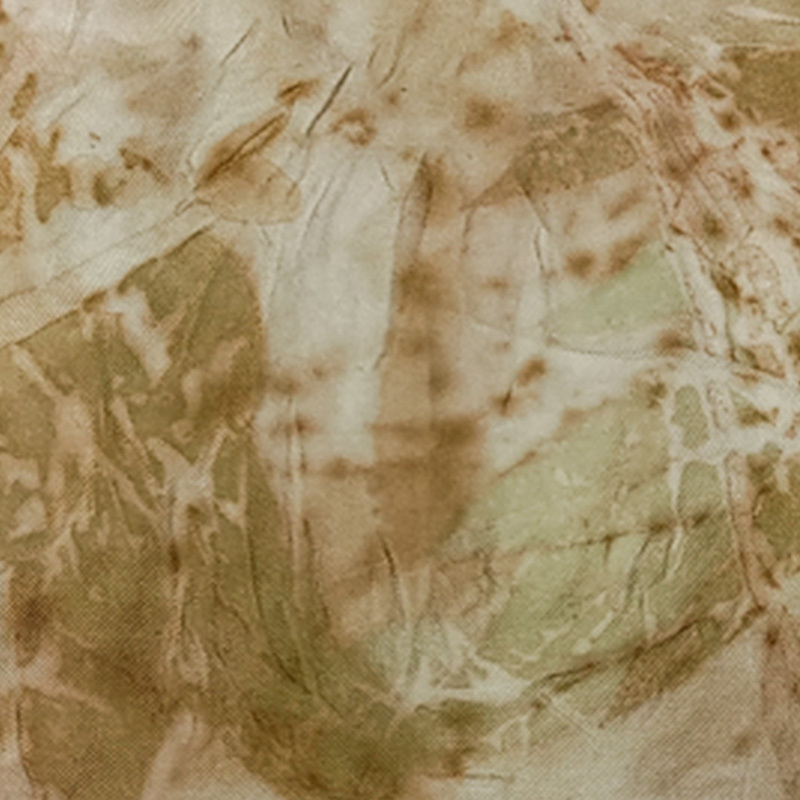

1. Why choose natural dye fabric?

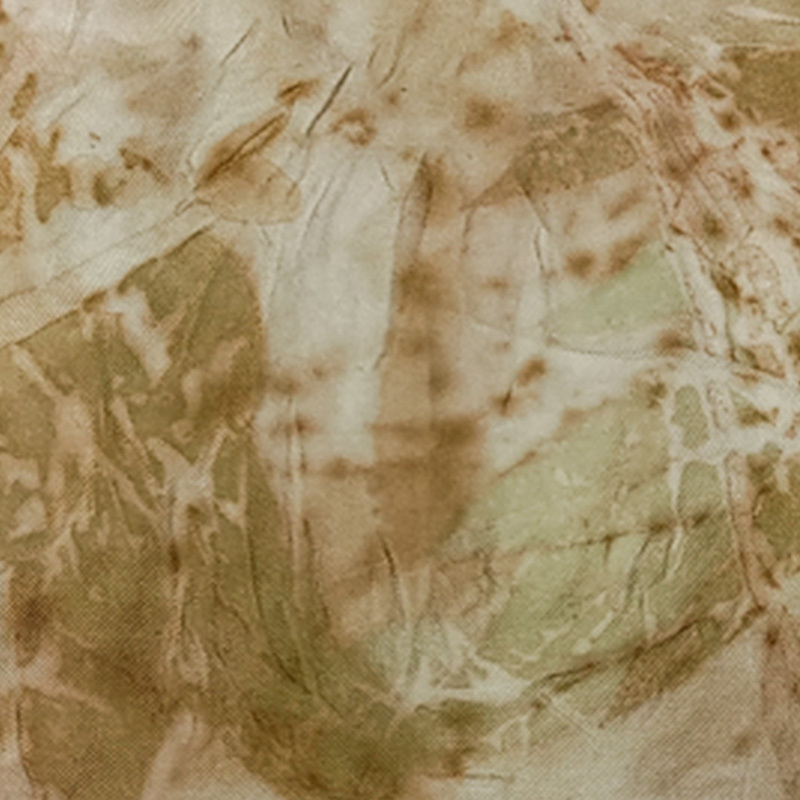

Natural dye fabric offers a softer aesthetic and lower environmental impact compared with many synthetic dyes when sourced and processed responsibly. Natural dyes—derived from plants, insects, and minerals—produce unique, often subtle color variations that become richer with age. Choosing natural-dyed textiles means considering provenance (are dyes harvested sustainably?), colorfastness expectations, and the fiber type you plan to dye.

2. Which fabrics take natural dyes best?

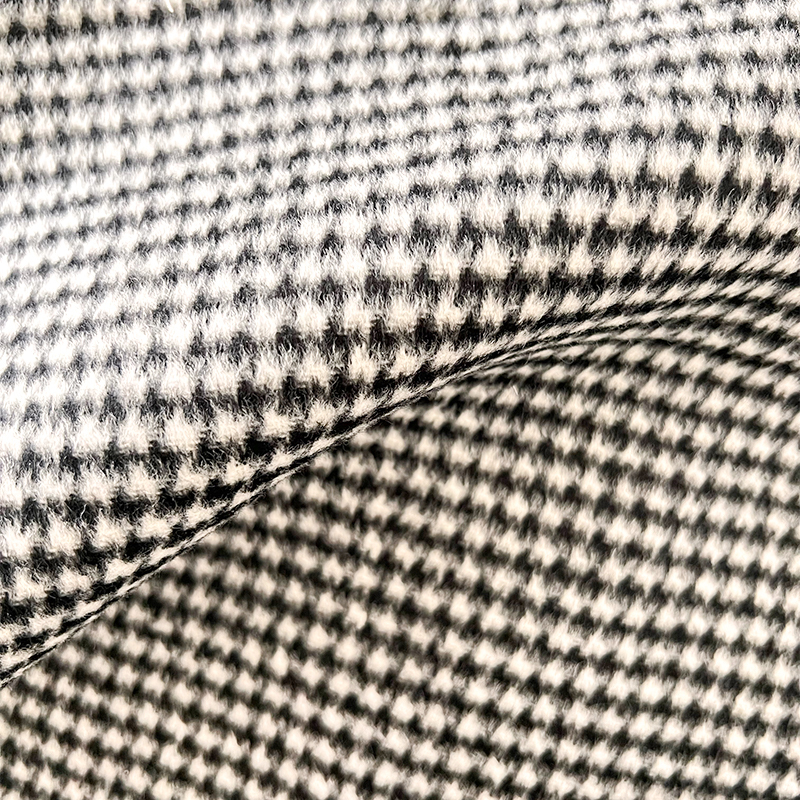

Not all fibers accept natural dyes equally. Protein and cellulose fibers behave differently: protein fibers (wool, silk) generally take natural dyes readily, producing vibrant results; cellulose fibers (cotton, linen) often require stronger mordanting or special mordants to achieve comparable depth. Below is a concise compatibility reference to help you select the right fabric for your project.

| Fiber | Ease of Dyeing with Natural Dyes | Typical Mordant | Notes |

| Wool | High | Alum or iron (to shift tone) | Takes rich, warm tones; gentle heat recommended. |

| Silk | High | Alum | Lustrous results; handle gently to avoid damage. |

| Cotton | Moderate | Alum + tannin (or commercial fiber reactive enhancers) | Requires stronger mordanting; expect more muted shades. |

| Linen | Moderate | Tannin then alum | Textural, matte finish; pre-treatment improves uptake. |

3. Preparing fabric: scouring and mordanting

Preparation is the step most likely to determine color evenness and fastness. Two essential preparatory steps are scouring (removing oils, sizing, and dirt) and mordanting (fixing the dye). For protein fibers, scouring in warm water with a mild soap is usually sufficient; cellulose fibers often benefit from a soda ash or soda ash + non-ionic detergent scour to remove natural waxes.

Scouring procedure

- Use a large pot — allow fabric to move freely to avoid uneven scouring.

- Temperature: 40–60°C for wool/silk (avoid higher heat); 60–90°C for cotton/linen.

- Rinse thoroughly until water runs clear.

Mordanting essentials

Common mordants include alum (potassium aluminum sulfate), iron (to darken or shift tones), and tannins (from oak galls, pomegranate rind, or tea) to help cellulose fibers accept dyes. Always follow safety guidelines: weigh mordant relative to dry fiber weight (for example, alum at 8–15% WOF—weight of fiber—for many recipes), wear gloves, and ventilate the area. Rinse mordanted fabric gently and allow to dry before dyeing or proceed wet for better penetration.

4. Extracting natural dyes and building a recipe

Extracting dye from plant material can be as simple as simmering chopped material in water or as involved as fractionating with solvents (the latter is uncommon for craft dyeing). Typical home-scale extraction uses a ratio by weight—commonly 1:5 to 1:10 (fiber:dyestuff). Record your recipe: weights, water volume, mordant used, temperature, and time; this practice ensures consistent repeatability.

Common dyestuffs and expected colors

- Madder root: warm reds to rusty orange (strong on protein fibers).

- Woad/Indigo: blue shades (indigo vat required for cellulose fibers).

- Walnut hulls: deep browns and sepia tones; very good fastness.

- Turmeric: bright yellow but poor lightfastness; best for decorative items.

5. Step-by-step natural dyeing process (practical)

Follow these steps for a reliable small-batch natural dyeing session. Quantities and times vary by dyestuff and desired depth; the procedure below is a practical starting point.

- Weigh materials: note dry fabric weight; calculate dyestuff and mordant percentages.

- Extract dye: simmer dyestuff in water for 30–60 minutes (longer for roots or hardwoods), then strain solids.

- Wet the mordanted fabric: add fabric to the dye bath while both dye and fabric are warm for best uptake.

- Maintain temperature: keep below a simmer for protein fibers; gentle simmer for cellulose fibers; stir occasionally to avoid uneven dyeing.

- Time: 30 minutes to several hours depending on desired depth; check color by removing a small wet sample and drying it to assess the true shade.

- Cool and rinse: allow the bath to cool, rinse fabric gently until water runs clear, then air dry away from direct sunlight to preserve color.

6. Aftercare and washing instructions for natural dye fabric

Proper aftercare preserves the appearance and fastness of natural-dyed textiles. Initial washes may release excess dye; wash separately in cool water with a mild detergent or soap suitable for delicates. Avoid chlorine bleach and prolonged sunlight exposure. For better long-term retention, recommend cold hand-washing or gentle machine cycles and line-drying in shade.

7. Troubleshooting common issues

Uneven color or streaks

Cause: insufficient scouring, overcrowded pot, or fabric not moving freely. Fix: re-scour fabric, redye in a larger bath with agitation, or use lower fabric-to-bath ratio next time.

Faded or weak color

Cause: weak dyestuff-to-fiber ratio, inadequate mordanting, or using a dye with poor lightfastness (e.g., some yellows). Fix: increase dyestuff or mordant percentage, or choose a more lightfast dyestuff.

8. Sustainable practices and safety notes

Prioritize sustainably harvested dyestuffs and safe disposal of spent dyebaths. Some natural mordants (e.g., iron, copper) can accumulate in the environment—use minimal effective quantities and neutralize baths before disposal according to local regulations. Always wear gloves and avoid inhaling powdered dyestuffs. For artisanal production, keep records of suppliers and batch recipes to maintain traceability and eco-compliance.

9. Quick reference: dos and don'ts

- Do test small swatches before committing to large pieces.

- Do weigh fibers and dyestuffs for repeatable results.

- Don't assume all plant sources are sustainable—verify supply chains.

- Don't use high heat on delicate protein fibers; it can felt or damage them.

Following these practical steps and recording your methods will help you achieve consistent, beautiful results when working with natural dye fabric. If you want, I can provide a printable recipe sheet template or a sample set of weight-based recipes for specific dyestuffs (madder, indigo, walnut) tailored to wool, silk, and cotton.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post