The dyeing and finishing problem of silk fabrics: the impact of natural fiber irregularity on color stability

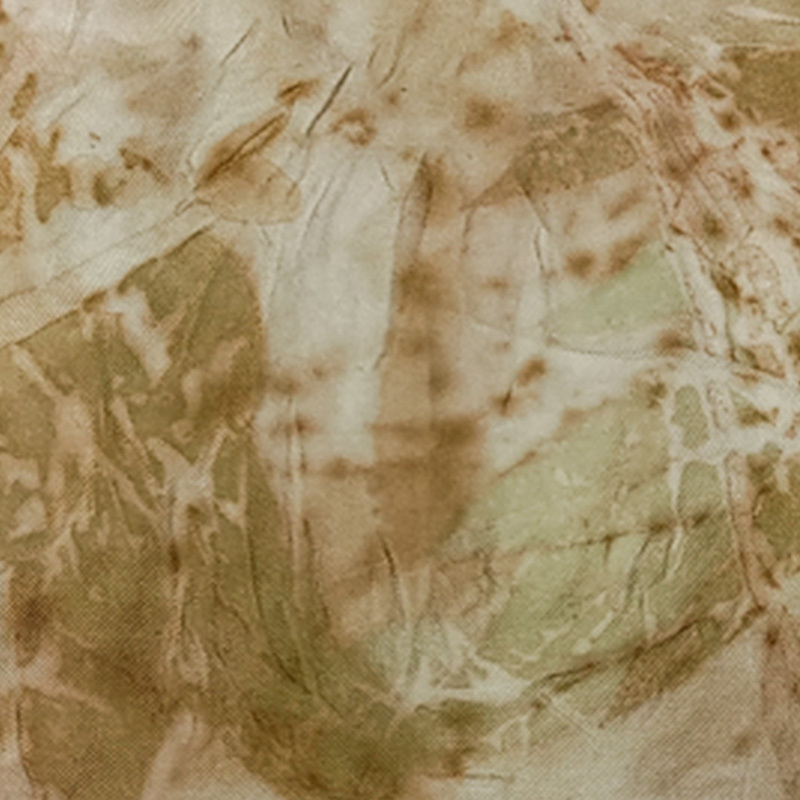

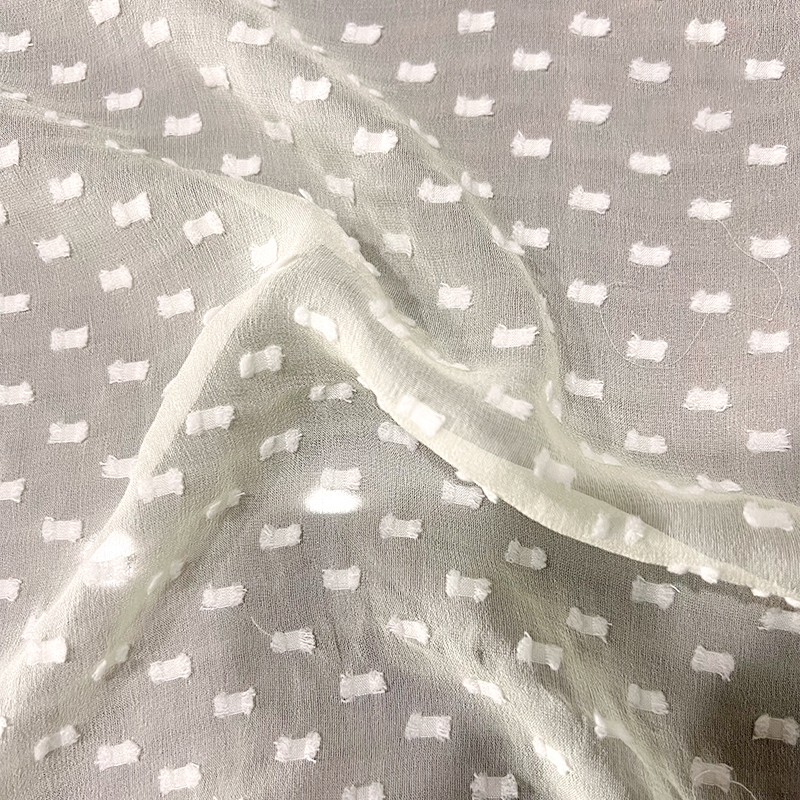

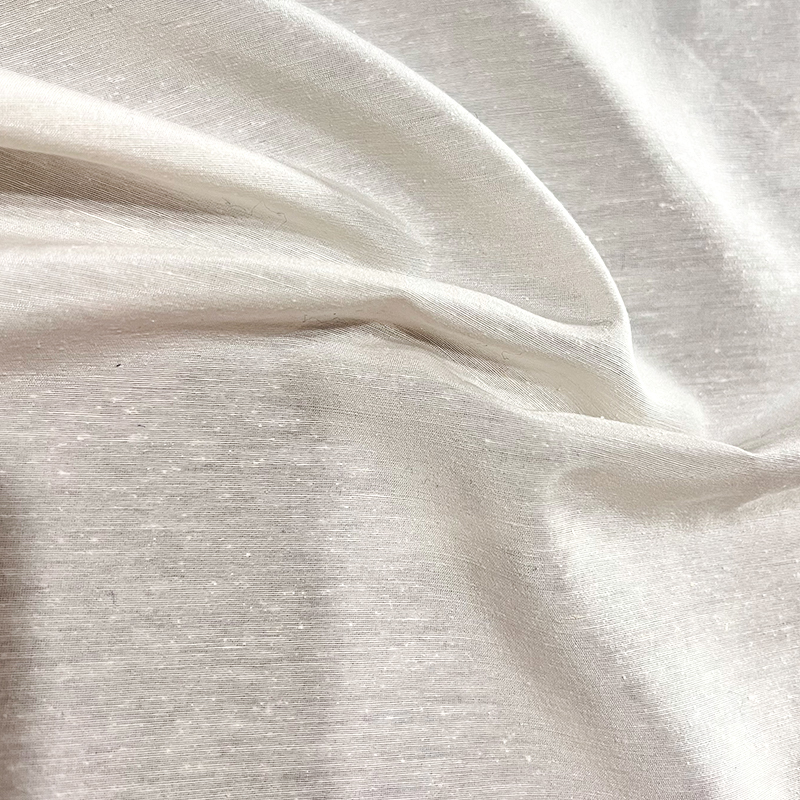

Silk fabrics (Noil Silk fabric) have gradually become a popular material in the field of sustainable fashion due to their natural luster, breathability and unique rough texture. However, the dyeing and finishing process in its production faces significant challenges - the irregular structure of natural fibers leads to poor color stability, which directly affects the quality and commercial value of the finished product.

The source of fiber irregularity

Silk is recombined from short fibers and waste silk in silk production. Its fibers have the following characteristics:

Uneven length: the interweaving of short fibers leads to an uneven surface of the fabric;

Diameter difference: fibers of different thicknesses have different rates of dye absorption;

Rough surface: porous structures are prone to adsorb impurities and interfere with dyeing uniformity.

These characteristics make the dye penetrate unevenly between fibers, prone to color spots and color differences, and easy to fade due to friction or washing after fixing (low color fastness).

The core contradiction of dyeing and finishing process

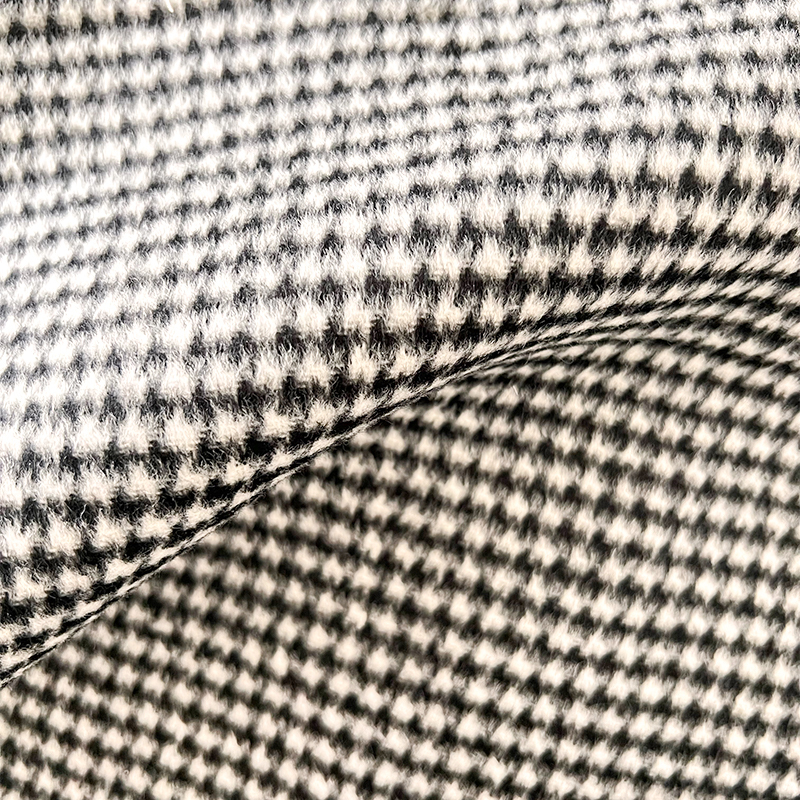

Traditional silk dyeing relies on the uniformity and smooth surface of the fiber, but the "defects" of silk have become its style label. In order to retain the natural texture, excessive chemical treatment should be avoided, which leads to a dilemma in the process:

Pretreatment problem: conventional refining (removal of sericin) will destroy the structure of short fibers and affect the fluffiness of the fabric;

Dye selection restrictions: although reactive dyes are environmentally friendly, they require high-salt media to promote dyeing, which aggravates fiber swelling and color flower risks;

Low fixation efficiency: irregular fibers have a large surface area, and traditional fixatives are difficult to cover evenly.

Innovative solutions

Biological enzyme pretreatment technology:

Use cellulase or protease to degrade impurities on the fiber surface in a directional manner, reduce the use of chemical reagents, and retain the natural texture of the fiber. Experiments show that enzyme treatment can improve dyeing uniformity by 20%-30%.

Low-salt reactive dyes and step-by-step dyeing:

Develop low-salt high-fixation dyes, combined with segmented temperature control dyeing (such as low-temperature penetration first, high-temperature fixation later), to reduce color differences caused by excessive fiber swelling.

Application of nano-fixatives:

Use nanoparticles (such as silica) to encapsulate the fixative to enhance its adhesion to the rough fiber surface and improve color fastness by 1-2 levels (ISO standard).

As environmental regulations become stricter, the development of bio-based dyes and waterless dyeing technology (such as supercritical CO₂ dyeing) may become a breakthrough point. In addition, the use of AI algorithms to predict the relationship between fiber structure and dyeing effect can achieve precise process control.

The dyeing and finishing problem of silk fabrics is essentially a game between natural materials and industrial standards. Only by balancing "defect aesthetics" and technological innovation can the maximum potential of this sustainable material be released.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post