What is the difference between spun silk and reeled silk?

Silk, prized for its luxurious texture and natural sheen, comes in various forms, among which spun silk and reeled silk are the most commonly discussed. Though both originate from the silk cocoon produced by silkworms, the processes used to extract the fibers and the resulting fabric characteristics differ significantly. Understanding the distinctions between these two types of silk is crucial for manufacturers, designers, and consumers who value both quality and functionality in textile applications.

Origin and Production Process

Reeled silk, also known as filament silk, is produced by unwinding long, continuous fibers directly from the intact cocoon. This process is delicate and labor-intensive, as it requires maintaining the cocoon's integrity during boiling and reeling. The silk filaments can be up to 1,000 meters long and are exceptionally smooth, making reeled silk the finest quality of silk available.

Spun silk fabric, on the other hand, is made from shorter fibers that are left over after the reeling process or obtained from damaged cocoons that cannot be reeled. These shorter fibers are carded and spun into yarn using a method similar to that of spinning cotton or wool. The resulting yarn is softer and more matte than reeled silk and often more affordable due to the use of byproducts.

Texture and Appearance

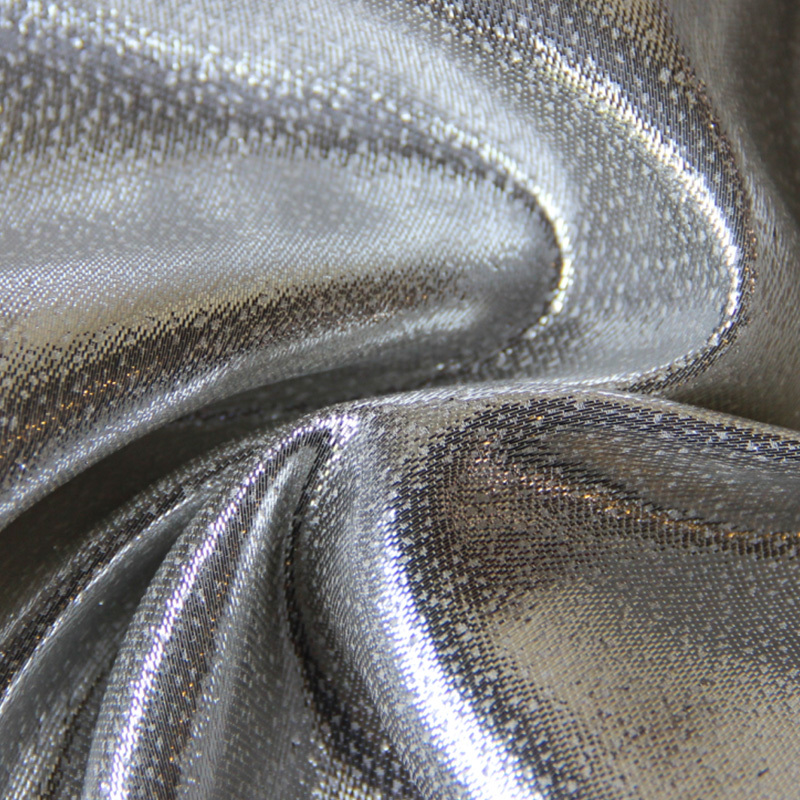

The physical differences between spun silk and reeled silk are most noticeable in their texture and visual finish. Reeled silk is lustrous, smooth, and has a fluid drape. Its surface reflects light beautifully, which makes it ideal for high-end garments, evening wear, and luxury home décor.

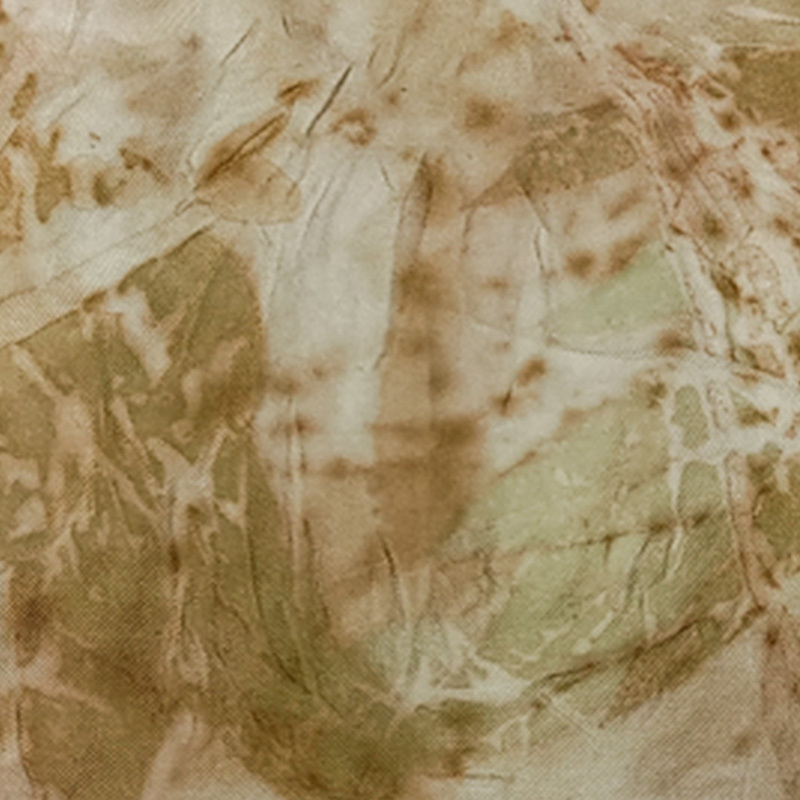

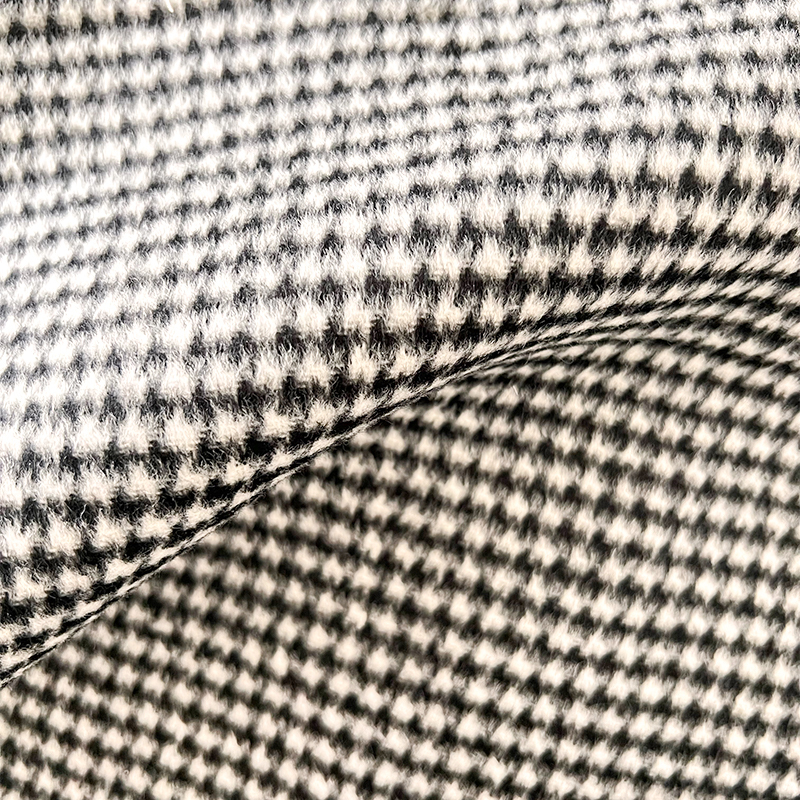

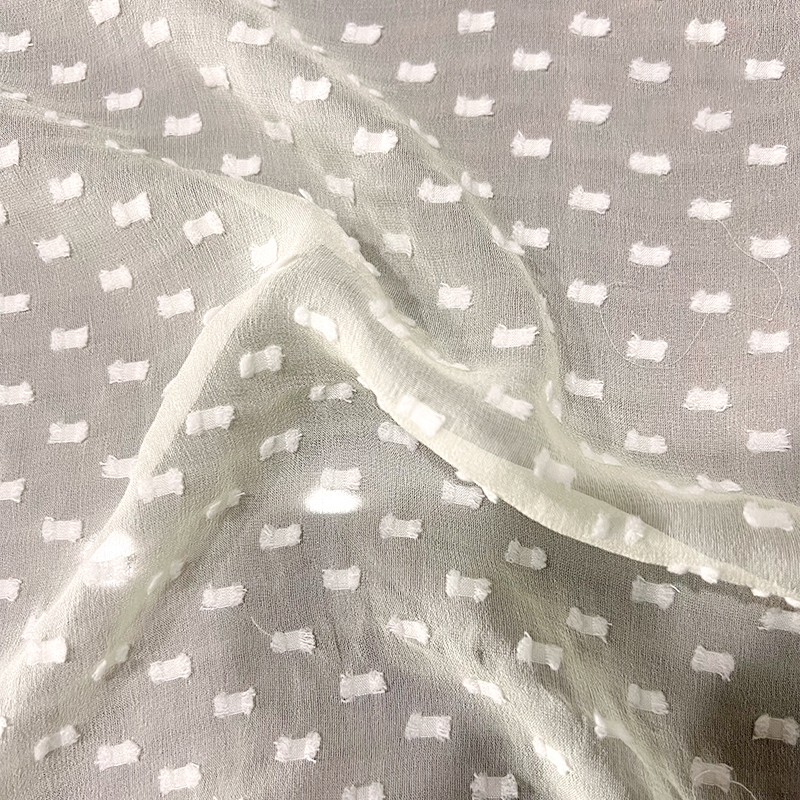

In contrast, spun silk has a slightly rougher texture and a more matte appearance. While still soft and elegant, it lacks the high sheen and fluidity of reeled silk. However, this makes it suitable for more casual or versatile applications where a muted elegance is preferred.

Durability and Performance

In terms of strength, reeled silk holds a clear advantage. The long, continuous filaments give it higher tensile strength, which means it’s less prone to fraying and can withstand more wear over time. This makes reeled silk ideal for garments that require longevity and a refined look.

Spun silk, being made from shorter fibers, is slightly less durable and more prone to pilling. However, it compensates by being more breathable and insulating, which is beneficial in applications like undergarments, scarves, or everyday clothing. It also absorbs dyes well, allowing for rich and uniform color finishes.

Cost and Sustainability

The production of reeled silk is more time-consuming and resource-intensive, resulting in a higher cost. It also involves boiling live cocoons to keep the fibers intact, which raises ethical concerns for some consumers.

Spun silk is generally more economical, as it makes use of waste materials from the silk production process. From a sustainability and waste-reduction perspective, spun silk offers a more eco-conscious alternative while still maintaining the inherent benefits of natural silk.

Common Uses

Reeled silk is typically used in:

Luxury apparel such as evening gowns and suits

High-end home textiles like silk bedding and curtains

Accessories including ties and high-gloss scarves

Spun silk finds its place in:

Casual fashion and everyday wear

Lightweight sweaters and underlayers

Blended fabrics and knitwear

Craft and embroidery threads

The primary difference between spun silk and reeled silk lies in the fiber length and extraction method. Reeled silk is a premium product with long, continuous fibers, offering high gloss and strength. Spun silk, while less lustrous and durable, is softer, more breathable, and often more sustainable. Choosing between the two depends on the intended use, desired aesthetic, and ethical considerations. Whether you seek the luxurious shine of reeled silk or the soft practicality of spun silk, both types showcase the enduring appeal of this timeless natural fiber.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post