What is Cotton Blend Fabric? Types, Benefits & Complete Guide

Cotton blend fabric represents a textile innovation that combines natural cotton fibers with other materials to create fabrics with enhanced properties and performance characteristics. Understanding cotton blend materials helps consumers make informed decisions about clothing, home textiles, and various fabric applications.

Content

- 1 Understanding Cotton Blend Fabric Composition

- 2 Common Types of Cotton Blend Materials

- 3 Key Benefits of Cotton Blend Fabrics

- 4 Comparison of Cotton Blends vs Pure Cotton

- 5 Proper Care and Maintenance of Cotton Blend Fabrics

- 6 Applications and Uses of Cotton Blend Materials

- 7 How to Identify and Choose Quality Cotton Blends

- 8 Environmental Considerations of Cotton Blends

- 9 Common Issues and Solutions with Cotton Blend Fabrics

Understanding Cotton Blend Fabric Composition

Cotton blend fabric is a textile material created by combining cotton fibers with one or more different fiber types during the manufacturing process. This blending occurs at the yarn production stage, where cotton is mixed with synthetic fibers like polyester, rayon, or spandex, or with other natural fibers such as linen or wool. The resulting fabric incorporates the beneficial qualities of each fiber type while minimizing their individual drawbacks.

The percentage composition of cotton blends varies widely depending on the intended use and desired characteristics. Common ratios include 80/20, 60/40, or 50/50 cotton-to-other-fiber blends. The dominant fiber typically determines the primary feel and behavior of the fabric, while the secondary fiber adds specific performance features. Manufacturers carefully engineer these ratios to achieve optimal balance between comfort, durability, and functionality.

The blending process fundamentally differs from layered fabrics or fabric treatments. True cotton blends integrate different fibers at the molecular level through spinning, creating a uniform textile where properties are evenly distributed throughout the material. This integration ensures consistent performance across the entire fabric rather than surface-level modifications.

Common Types of Cotton Blend Materials

Cotton-Polyester Blends

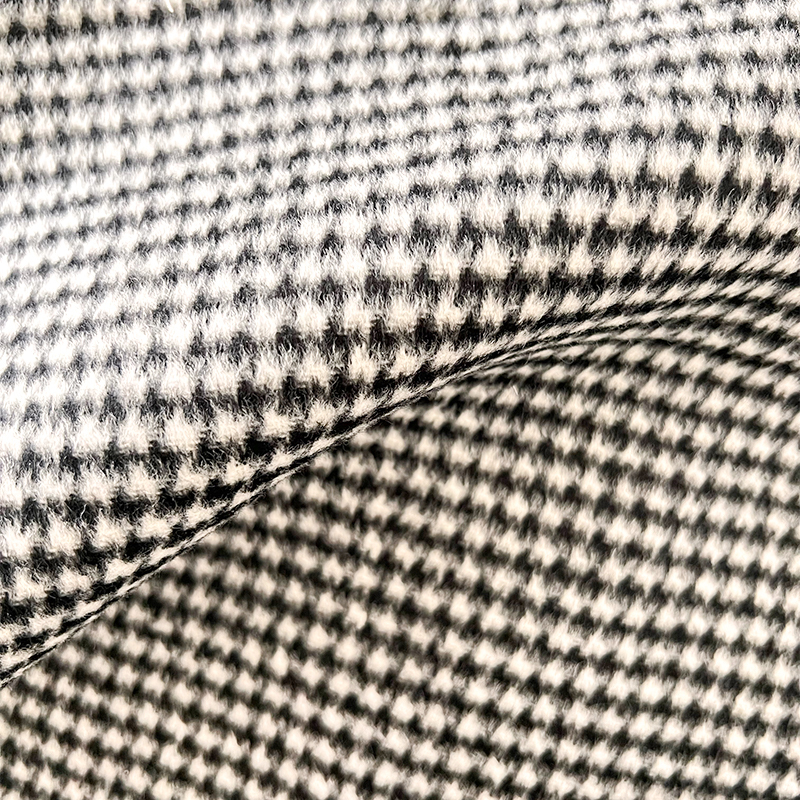

Cotton-polyester represents the most widespread cotton blend in the textile industry. This combination typically ranges from 50/50 to 65/35 cotton-to-polyester ratios. The polyester component adds wrinkle resistance, dimensional stability, and increased durability to cotton's natural breathability and softness. These blends are extensively used in dress shirts, workwear, bed sheets, and everyday casual clothing due to their easy-care properties and long-lasting performance.

Cotton-Spandex Blends

Cotton-spandex blends incorporate small percentages of elastane (typically 2-5%) into cotton fabric to provide stretch and recovery properties. This blend maintains cotton's breathability while adding flexibility and shape retention. The material is ideal for activewear, fitted clothing, jeans, and garments requiring body-hugging comfort without sacrificing the natural feel of cotton.

Cotton-Rayon Blends

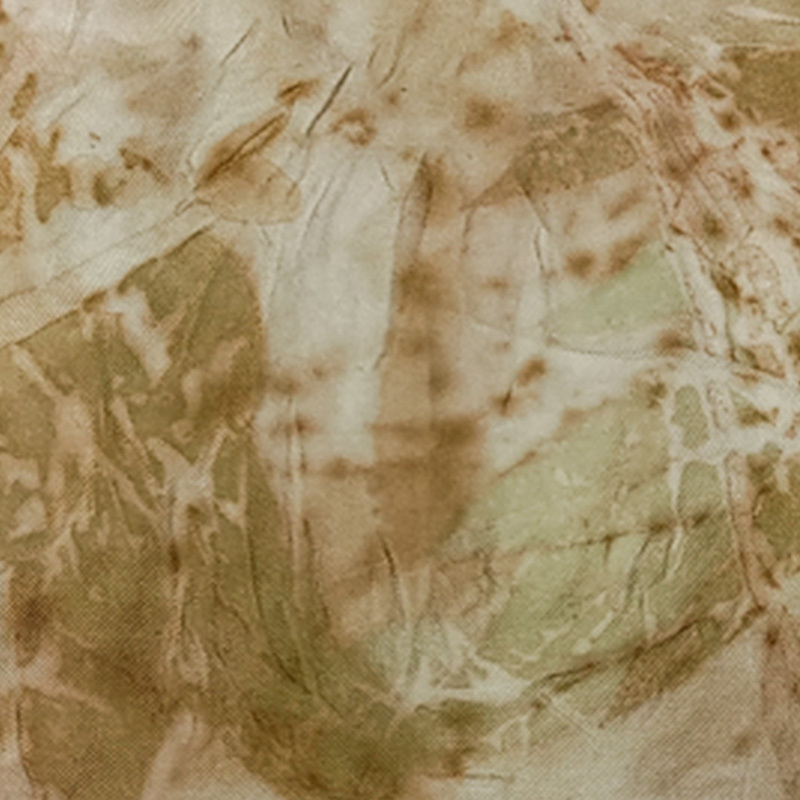

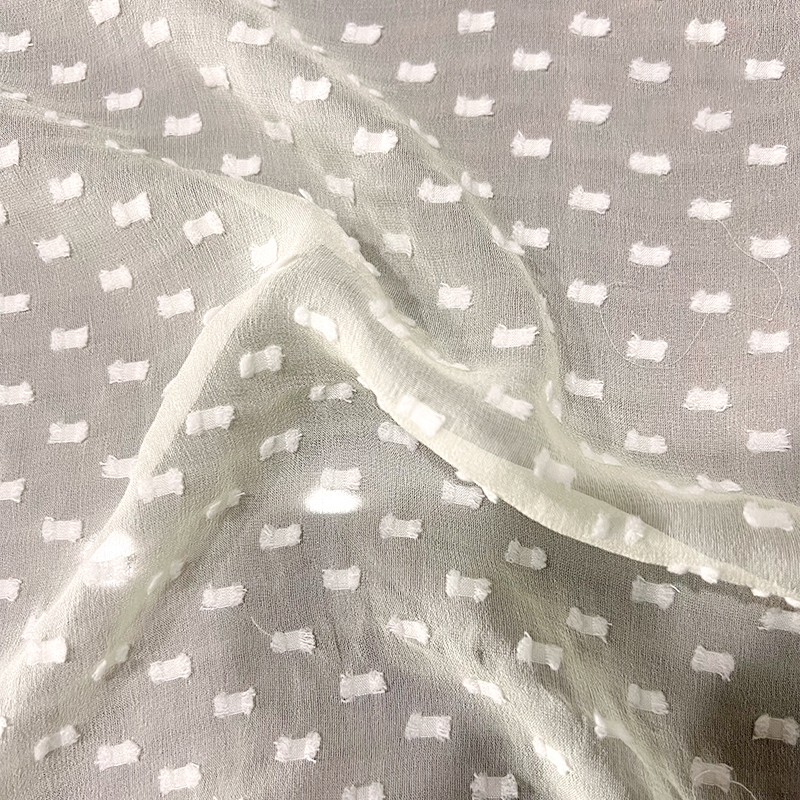

Cotton-rayon combinations merge two cellulose-based fibers to create fabrics with enhanced drape and a silky texture. Rayon adds fluidity and sheen to cotton's structure, resulting in fabrics that are lightweight, breathable, and have an elegant appearance. These blends commonly appear in dresses, blouses, and flowing garments where movement and aesthetic appeal are priorities.

Cotton-Linen Blends

Combining cotton with linen creates a fabric that balances linen's crisp texture and excellent breathability with cotton's softness and reduced wrinkling tendency. This natural fiber blend is particularly popular for summer clothing, home textiles, and casual wear where comfort in warm weather is essential while maintaining a more refined appearance than pure linen.

Cotton-Modal Blends

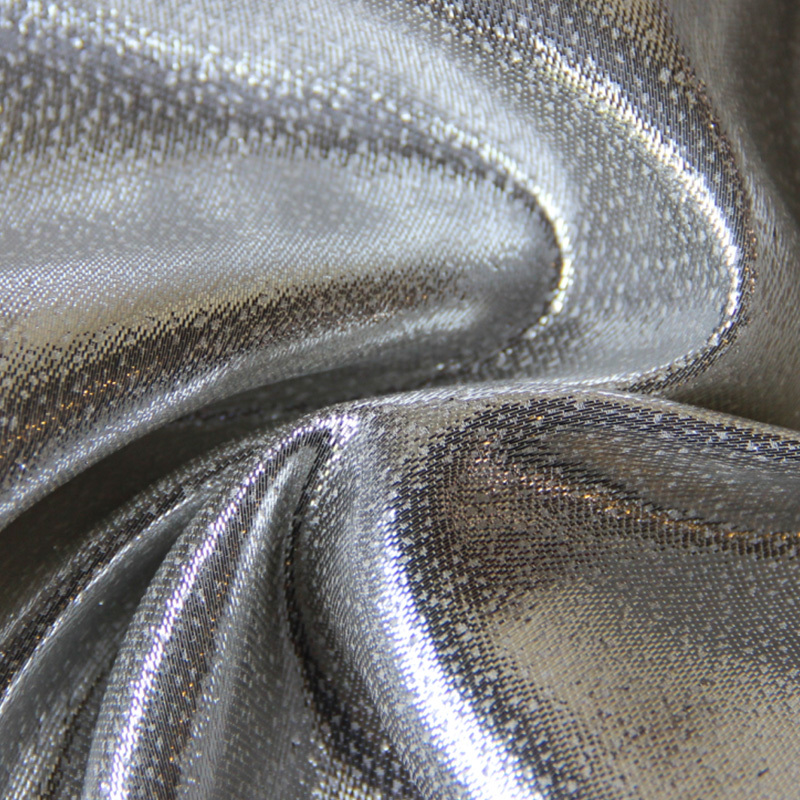

Modal, a semi-synthetic fiber derived from beech tree pulp, blends with cotton to produce exceptionally soft, smooth fabrics with excellent color retention and resistance to shrinkage. Cotton-modal blends offer superior comfort for underwear, loungewear, and premium t-shirts, combining sustainability with luxurious hand feel.

Key Benefits of Cotton Blend Fabrics

- Enhanced durability and longevity compared to 100% cotton, as synthetic fibers strengthen the fabric structure and resist wear and tear from repeated washing and use

- Improved wrinkle resistance that reduces or eliminates the need for ironing, saving time and maintaining a polished appearance throughout the day

- Better shape retention and dimensional stability, meaning garments maintain their original fit and proportions even after multiple wash cycles

- Faster drying times due to synthetic fibers' moisture-wicking properties, which reduce laundry time and energy consumption

- Cost-effectiveness as blending cotton with less expensive fibers reduces production costs while maintaining quality and performance

- Reduced shrinkage compared to pure cotton fabrics, ensuring garments maintain their size specifications after washing

- Versatile performance characteristics tailored to specific applications, from athletic wear to professional attire to home furnishings

- Color vibrancy and retention, as synthetic fibers typically hold dyes more effectively than pure cotton, resulting in longer-lasting, brighter colors

Comparison of Cotton Blends vs Pure Cotton

| Characteristic | Cotton Blend | Pure Cotton |

| Breathability | Good to Moderate | Excellent |

| Wrinkle Resistance | High | Low |

| Durability | Higher | Moderate |

| Shrinkage | Minimal | Moderate to High |

| Moisture Absorption | Moderate | Excellent |

| Drying Time | Faster | Slower |

| Static Electricity | Higher (with synthetics) | Low |

| Price | Generally Lower | Higher |

| Environmental Impact | Mixed (depends on blend) | Better (biodegradable) |

Proper Care and Maintenance of Cotton Blend Fabrics

Washing Guidelines

Cotton blend fabrics generally tolerate machine washing well, but specific care depends on the blend composition. For cotton-polyester blends, use warm or cold water to prevent any potential shrinkage and maintain color vibrancy. Cotton-spandex blends require cold water washing to preserve the elastic fibers and prevent degradation. Always separate dark colors from light colors during the first few washes to prevent color transfer, and turn garments inside out to protect the fabric surface and printed designs.

Select a gentle or normal cycle depending on the garment type and soil level. Heavily soiled workwear can withstand regular cycles, while delicate blouses or athletic wear benefit from gentle cycles. Use mild detergents without bleach for most cotton blends, as harsh chemicals can damage synthetic fibers and cause premature wear. Avoid overloading the washing machine to ensure proper cleaning and reduce wrinkling.

Drying Methods

Cotton blends dry faster than pure cotton due to synthetic fibers' lower moisture retention. Machine drying on low to medium heat works well for most cotton-polyester blends, though removing items while slightly damp prevents over-drying and reduces wrinkles. Cotton-spandex blends should always be dried on low heat or air-dried to maintain elasticity. High heat can damage elastic fibers and cause them to lose their stretch properties permanently.

Air drying remains the gentlest option for all cotton blends and extends garment life significantly. Hang items on padded hangers or lay flat to dry, avoiding direct sunlight which can fade colors over time. For wrinkle-prone items, remove from the dryer immediately and hang or fold to minimize creasing.

Ironing and Pressing

One major advantage of cotton blends is reduced ironing requirements. When ironing becomes necessary, use moderate heat settings appropriate for synthetic fibers rather than the high heat used for pure cotton. Cotton-polyester blends typically require medium heat, while cotton-spandex should never be ironed at high temperatures. Always check garment care labels for specific temperature recommendations and test on an inconspicuous area first.

Applications and Uses of Cotton Blend Materials

Apparel and Fashion

Cotton blend fabrics dominate the ready-to-wear clothing industry due to their versatility and performance. T-shirts commonly use cotton-polyester blends for durability and easy care, while dress shirts favor higher cotton content blends for comfort with added wrinkle resistance. Athletic wear extensively incorporates cotton-spandex and cotton-polyester-spandex tri-blends that provide moisture management, stretch, and breathability for active movement.

Denim manufacturers increasingly use cotton-spandex blends to create stretch jeans that offer comfort and flexibility while maintaining the classic denim aesthetic. Workwear relies heavily on cotton-polyester blends for their exceptional durability, stain resistance, and ability to withstand frequent industrial laundering. Casual wear, from sweatshirts to yoga pants, benefits from various cotton blend formulations tailored to specific activity levels and comfort requirements.

Home Textiles

Bedding products frequently feature cotton-polyester blends that combine cotton's softness with polyester's wrinkle resistance and durability. Sheet sets, duvet covers, and pillowcases made from blends require less maintenance than pure cotton alternatives while providing comfortable sleep surfaces. The blend ratio in bedding typically favors higher cotton content (60-80%) to maximize breathability and comfort while gaining practical benefits from synthetic fiber addition.

Towels, curtains, and upholstery also utilize cotton blends for enhanced performance characteristics. Cotton-linen blend curtains offer elegant drape with improved wrinkle resistance, while cotton-polyester upholstery fabrics provide stain resistance and longevity in high-traffic furniture applications.

Industrial and Commercial Applications

Medical scrubs and uniforms predominantly use cotton-polyester blends for their ability to withstand rigorous sterilization processes while maintaining color and shape. Hospitality industries select cotton blend linens for hotels and restaurants that balance guest comfort with commercial laundering demands. Promotional products like custom t-shirts and tote bags favor cotton blends for cost-effectiveness and printing compatibility across various decoration methods.

How to Identify and Choose Quality Cotton Blends

Reading Fabric Labels

Quality cotton blends always include fiber content labels listing the percentage of each material in descending order by weight. A label reading "60% Cotton, 40% Polyester" indicates cotton as the primary fiber. Reputable manufacturers provide complete composition information, washing instructions, and country of origin. Absence of detailed labeling often signals lower quality products or non-compliance with textile labeling regulations.

Look for specific certifications that indicate quality standards, such as OEKO-TEX certification for harmful substance testing or organic cotton certifications when applicable. These third-party validations ensure the fabric meets safety and quality benchmarks beyond basic fiber content disclosure.

Physical Assessment

Examine fabric weight and density by holding the material up to light. Quality blends have consistent weave density without thin spots or irregularities. Feel the fabric texture—it should be smooth without excessive pilling, rough patches, or loose threads. Higher quality cotton blends maintain softness while having substantial hand feel rather than feeling papery or excessively thin.

Test the fabric's recovery by crushing a small section in your hand and releasing it. Quality blends spring back relatively quickly with minimal wrinkling, demonstrating good resilience. Check seam quality and stitching consistency, as manufacturers using quality fabrics typically employ better construction techniques throughout the garment.

Selecting the Right Blend Ratio

Choose blend ratios based on intended use and personal priorities. For maximum comfort and breathability with some easy-care benefits, select blends with 70% or higher cotton content. For maximum durability and wrinkle resistance in work or travel situations, 50/50 or 60/40 cotton-polyester blends provide optimal performance. Athletic and active wear performs best with lower cotton percentages (40-60%) combined with polyester and small amounts of spandex for moisture management and stretch.

Consider climate and season when selecting blends. Higher cotton content suits warm weather and direct skin contact, while balanced blends work well for layering pieces and cooler conditions. For those with sensitive skin, prioritize higher cotton content and avoid blends with excessive synthetic fibers that may cause irritation.

Environmental Considerations of Cotton Blends

The environmental impact of cotton blend fabrics represents a complex balance between natural and synthetic fiber production. Cotton cultivation requires significant water resources and often involves pesticide use, though organic cotton options mitigate some concerns. Synthetic fibers like polyester derive from petroleum-based sources and contribute to microplastic pollution through washing, yet they require less water in production and create durable products that need less frequent replacement.

Cotton blends present recycling challenges because separating different fiber types proves difficult with current technology. Most textile recycling facilities cannot efficiently process blended fabrics, leading many cotton blend garments to end up in landfills. However, the extended lifespan of quality cotton blends compared to pure cotton can offset some environmental concerns through reduced consumption and production frequency.

Emerging technologies focus on creating more sustainable cotton blends using recycled polyester, organic cotton, or innovative natural fibers like Tencel or bamboo-derived rayon. These developments aim to maintain the performance benefits of blended fabrics while reducing environmental footprint. Consumers seeking eco-friendly options should look for blends featuring recycled content, organic certifications, or semi-synthetic fibers from sustainable forestry sources.

Common Issues and Solutions with Cotton Blend Fabrics

Pilling Problems

Pilling occurs when short fibers work their way to the fabric surface and tangle into small balls, particularly common in cotton-polyester blends. This happens due to friction during wear and washing. Prevent pilling by washing garments inside out, using gentle cycles, and avoiding overloading the washing machine. Remove existing pills with a fabric shaver or pill comb rather than picking them by hand, which can damage the fabric structure. Higher quality blends with longer staple fibers pill less than cheaper alternatives.

Static Electricity

Synthetic fibers in cotton blends can generate static electricity, especially in dry conditions. Reduce static by using fabric softener in the wash or dryer sheets during drying. Alternative solutions include adding white vinegar to the rinse cycle or using wool dryer balls. For immediate relief, lightly mist garments with water or use anti-static spray before wearing.

Color Fading

While cotton blends generally retain color better than pure cotton, dark colors can still fade over time. Preserve color by washing in cold water, turning garments inside out, and using color-safe detergents. Avoid excessive sun exposure during drying and limit the use of harsh chemicals. Some fading is natural and unavoidable with repeated washing, but proper care significantly extends color vibrancy.

Odor Retention

Synthetic fibers can trap odors more readily than natural cotton, particularly in athletic wear. Combat this by washing garments promptly after wear, using enzyme-based detergents designed for activewear, and adding baking soda or white vinegar to wash cycles. Avoid fabric softeners on athletic cotton blends as they can coat fibers and worsen odor retention. Air-drying in sunlight provides natural antibacterial benefits that help eliminate persistent odors.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post