How does the dyeing process of natural dye fabric differ from that of synthetic dye fabric?

The art of dyeing fabrics is one of the oldest and most significant practices in the textile industry. For centuries, people have relied on natural sources such as plants, minerals, and insects to add color to fibers and fabrics. With the industrial revolution and the rise of chemical sciences, synthetic dyes gradually replaced natural dyes due to their consistency, affordability, and wide color range. Today, both natural and synthetic dyeing processes exist, but they differ greatly in origin, technique, performance, and sustainability. Understanding these differences provides insight into the past and future of textile coloring.

Origins of Dyes

Natural dyes are derived from renewable resources found in nature. Plants such as indigo, madder, turmeric, and pomegranate rind have been traditional sources for blue, red, yellow, and brown shades. Insects like cochineal provide vivid crimson tones, while minerals such as ochre contribute earthy hues. These raw materials must be harvested, prepared, and processed to release their coloring compounds.

Synthetic dyes, in contrast, are manufactured through chemical synthesis, typically from petrochemical derivatives. The first synthetic dye, mauveine, was accidentally discovered in 1856 by William Henry Perkin. Since then, thousands of dye types have been created, allowing a much broader spectrum of colors and shades than nature alone can provide.

Fabric Preparation and Mordanting

One of the key differences in the dyeing process lies in how fabrics are prepared before coloring. Natural dyeing often requires a pretreatment step known as mordanting. Mordants are substances, traditionally metallic salts such as alum, copper, or iron, that bind the dye molecules to the fibers, improving color uptake and fastness. Without mordants, many natural dyes would wash out easily or appear dull. In some cases, tannins from plants are used as a natural mordant alternative.

Synthetic dyes generally do not require mordants because they are chemically engineered to have a strong affinity for particular fibers. For example, reactive dyes form covalent bonds with cotton, while acid dyes bond ionically with wool and silk. This built-in compatibility eliminates the need for an additional mordanting step and simplifies the dyeing process.

The Dyeing Process Itself

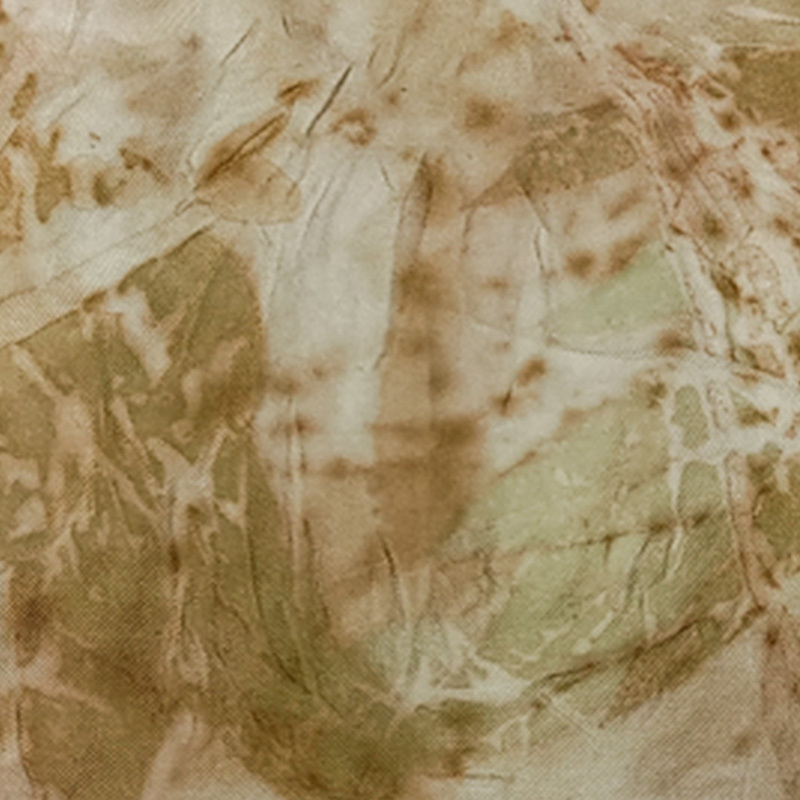

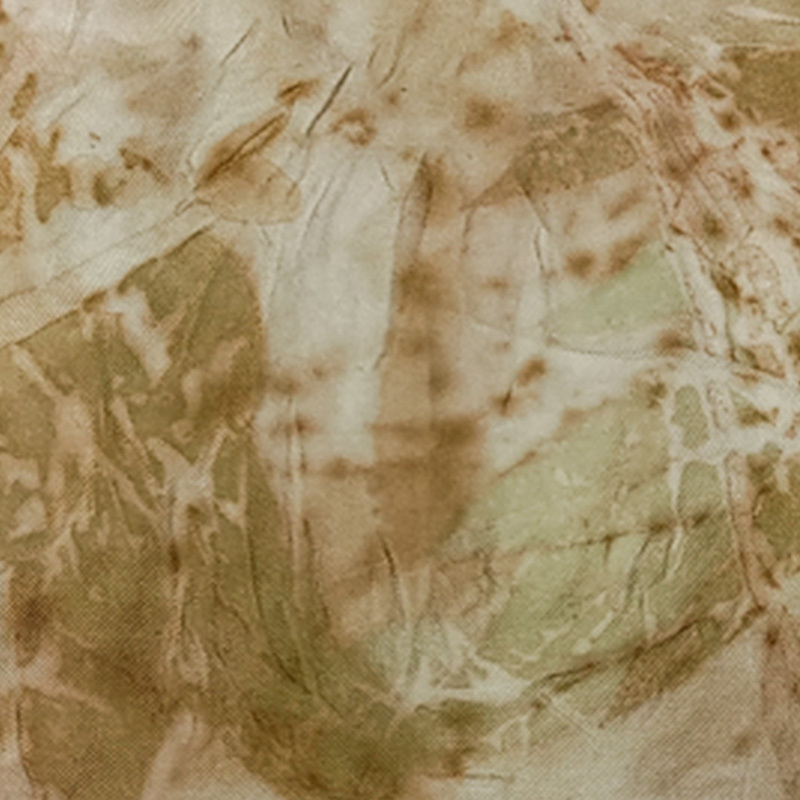

When dyeing with natural materials, the dye must first be extracted from its source. For plant-based dyes, this often involves boiling leaves, roots, bark, or flowers in water to release the color. The resulting solution becomes the dye bath. The fabric, already pretreated with a mordant, is then immersed in the bath for an extended period, sometimes hours, to allow the fibers to absorb the natural pigments. Temperature, pH, water quality, and even the season in which the plant was harvested can affect the outcome. The process is more craft-based than industrial, and results can vary from batch to batch.

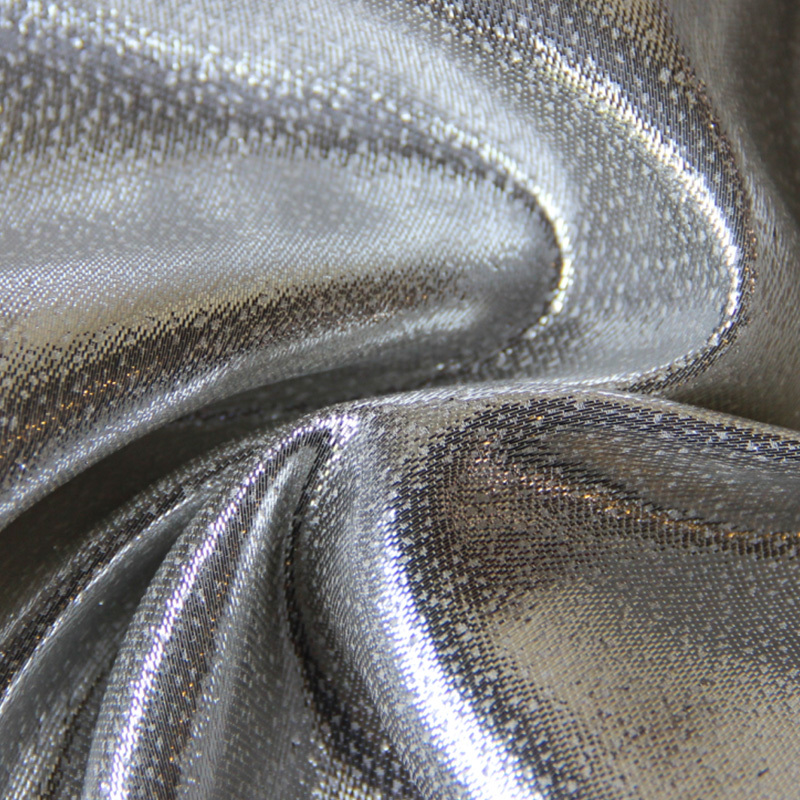

Synthetic dyeing is more controlled and efficient. Dyes are produced in powdered or liquid form, ready to dissolve directly into the dye bath. Parameters such as temperature, dye concentration, and duration are carefully monitored to achieve consistent, repeatable results. In industrial settings, automated dyeing machines can handle large volumes of fabric, ensuring uniformity across production runs. The process is faster and more scalable than natural dyeing.

Color Range and Consistency

Natural dyes typically produce earthy, muted shades such as soft blues, warm reds, golden yellows, and browns. While beautiful, the color palette is limited compared to synthetic options. Moreover, the same dye source can yield slightly different results depending on the water used, the fabric type, or even the dyeing season. This unpredictability can be appealing in artisanal or handmade textiles but presents challenges in mass production.

Synthetic dyes, by contrast, offer an almost unlimited spectrum of colors, including neon brights and deep saturated tones that are difficult to achieve naturally. Because synthetic dyes are chemically standardized, manufacturers can reproduce the same shade repeatedly with high precision, a critical requirement for large-scale fashion and textile industries.

Environmental Impact

The environmental implications of dyeing methods are increasingly important in the modern textile industry. Natural dyeing, when carried out using eco-friendly mordants and sustainable harvesting practices, can be less polluting than synthetic dyeing. The raw materials are renewable, biodegradable, and non-toxic. However, some traditional mordants like chromium are highly toxic and can offset the environmental benefits if used improperly. Additionally, natural dyeing often requires large amounts of plant material and water, raising concerns about resource use.

Synthetic dyeing is efficient and cost-effective, but it is also a significant contributor to industrial water pollution. Many synthetic dyes and auxiliary chemicals are not biodegradable and may contaminate water bodies if wastewater treatment is inadequate. The production of synthetic dyes also relies heavily on petroleum-based raw materials, linking it to broader issues of fossil fuel dependence and carbon emissions.

Durability and Performance

Another key distinction lies in colorfastness, or the ability of a dye to resist fading from washing, sunlight, or abrasion. Synthetic dyes generally outperform natural dyes in this respect. They are designed to form strong bonds with fibers and maintain color intensity over time.

Natural dyes can sometimes fade more quickly, especially when exposed to prolonged sunlight. However, the use of certain mordants or dyeing techniques can improve their durability. While they may not achieve the same level of resistance as synthetic dyes, natural dye fabrics often age gracefully, with colors softening into pleasing tones rather than looking worn out.

Cultural and Aesthetic Dimensions

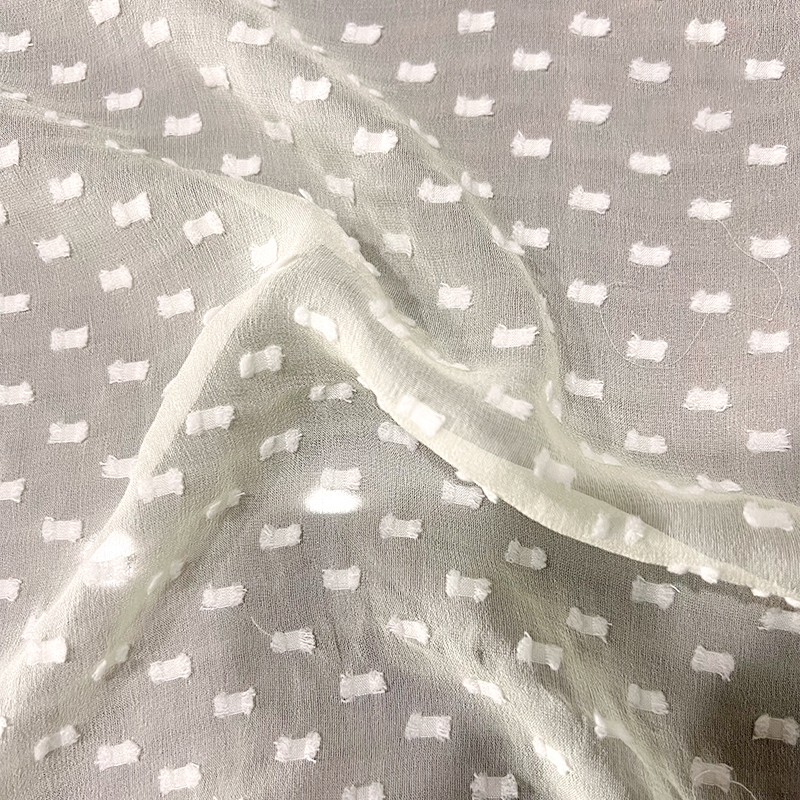

Beyond technical differences, the two dyeing methods carry cultural and aesthetic significance. Natural dyeing is deeply rooted in tradition and craftsmanship, often linked to specific regions, rituals, and heritage textiles. It is valued for its authenticity, uniqueness, and connection to nature. Each piece of naturally dyed fabric can be seen as one-of-a-kind, reflecting the subtle variations of the process.

Synthetic dyeing, on the other hand, represents industrial efficiency, modern fashion demands, and mass production. It enables designers to work with a vast palette, meet consumer expectations for consistency, and align with global supply chains.

Conclusion

The dyeing process of natural dye fabric differs from that of synthetic dye fabric in nearly every aspect—from raw materials and preparation to environmental impact and long-term performance. Natural dyeing is rooted in tradition, craftsmanship, and sustainability ideals, though it faces challenges in scalability and consistency. Synthetic dyeing dominates modern industry due to its precision, durability, and vast color range, yet it also raises concerns about ecological sustainability.

As the textile sector moves toward greener practices, there is growing interest in combining the best of both worlds: reviving natural dyeing methods with modern innovations while also developing more sustainable synthetic alternatives. Ultimately, both natural and synthetic dye fabrics hold value, and understanding their differences allows consumers, designers, and manufacturers to make informed choices.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post