What Makes Burnout Velvet Fabric Stand Out in Interior and Apparel Design

Content

- 1 Distinctive Surface Structure Created by the Burnout Process

- 2 Material Composition and Its Impact on Performance

- 3 Light Interaction and Visual Depth in Interior Spaces

- 4 Design Flexibility in Apparel Construction

- 5 Practical Considerations for Durability and Maintenance

- 6 Why Burnout Velvet Remains Relevant Across Design Fields

Distinctive Surface Structure Created by the Burnout Process

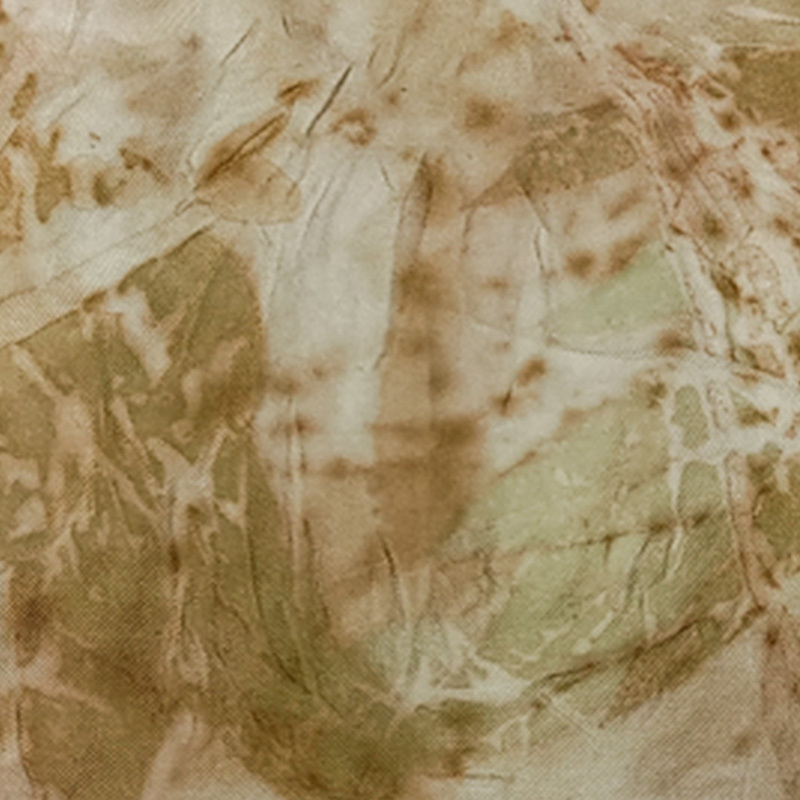

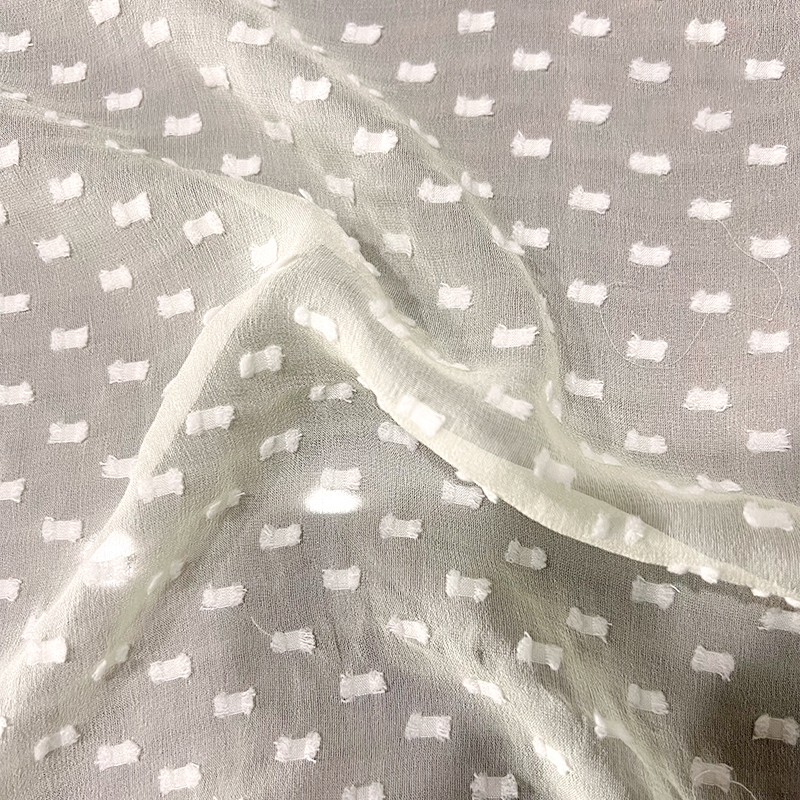

Burnout velvet fabric stands out primarily because of its unique surface structure, which is formed through a controlled chemical process rather than weaving alone. During production, selected fibers are dissolved from a blended fabric, leaving behind transparent or semi-sheer areas that contrast sharply with dense velvet pile. This technique allows intricate patterns to be integrated directly into the fabric rather than printed on the surface, resulting in a tactile and visual depth that is difficult to replicate with other textile methods.

For both interior and apparel applications, this structural contrast creates a layered appearance where light, texture, and pattern interact dynamically. Designers value this effect because it remains stable over time and does not rely on surface coatings or added embellishments that may degrade with use.

Material Composition and Its Impact on Performance

Burnout velvet fabric is typically produced using blended fibers, such as rayon with polyester or silk with viscose. The selective removal of one fiber type determines the final pattern and transparency. This composition directly influences drape, durability, and care requirements, making material selection a critical step for both residential textiles and garments.

- Rayon-based burnout velvet offers soft drape and strong visual contrast, commonly used in apparel and decorative panels.

- Polyester blends provide improved dimensional stability and abrasion resistance, suitable for curtains and light upholstery.

- Silk blends emphasize natural sheen and refined texture, often applied in high-end fashion and boutique interiors.

Light Interaction and Visual Depth in Interior Spaces

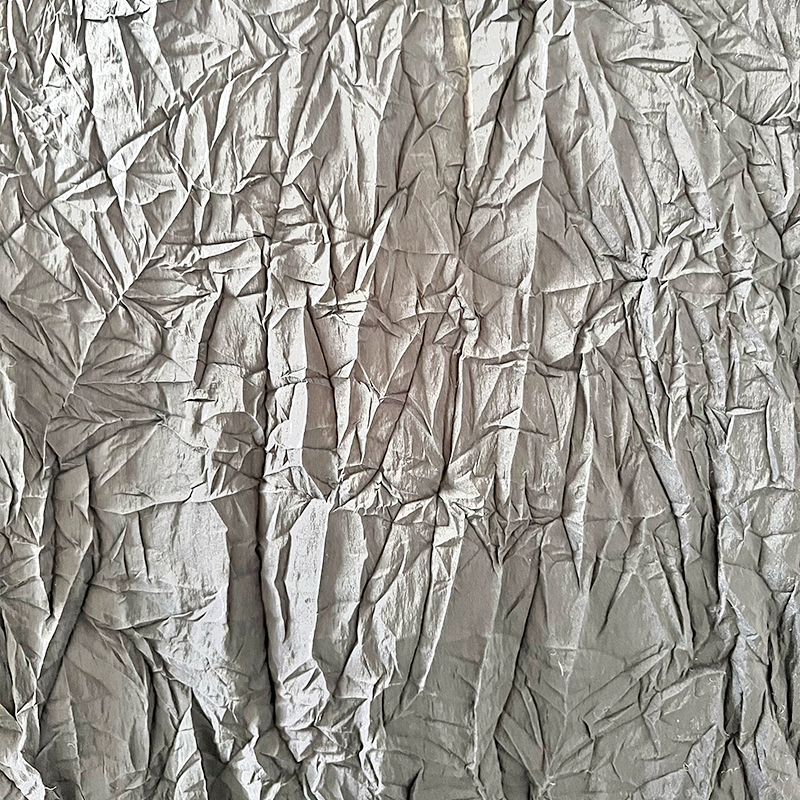

In interior design, burnout velvet fabric is frequently selected for its interaction with natural and artificial light. The contrast between opaque velvet areas and sheer sections allows light to pass through selectively, creating shadow patterns and depth without the need for additional layers. This makes the fabric particularly effective for window treatments, room dividers, and decorative drapery.

When used in hospitality or retail interiors, burnout velvet helps define spaces while maintaining visual openness. The fabric softens light diffusion while preserving privacy, a balance that is difficult to achieve with solid velvet or fully sheer textiles.

Design Flexibility in Apparel Construction

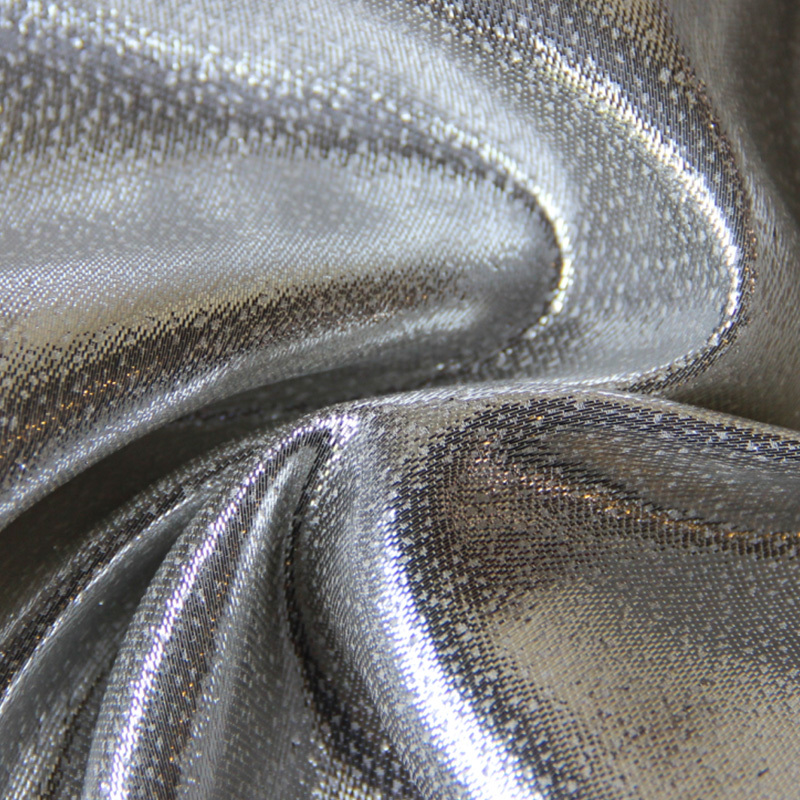

In apparel design, burnout velvet fabric provides structural and aesthetic flexibility. The variation in fabric density allows garments to highlight specific areas of the body through pattern placement rather than tailoring alone. Designers often use this feature to create visual rhythm across dresses, tops, and performance costumes.

Because the sheer sections are integrated into the fabric, burnout velvet reduces the need for additional panels or inserts. This simplifies garment construction while maintaining complex visual results, especially in eveningwear and stage costumes.

Pattern Placement and Garment Balance

Careful alignment of burnout patterns is essential during cutting and sewing. Symmetry, grain direction, and pile orientation must be considered together to avoid visual distortion. This requirement encourages more intentional pattern planning compared to standard velvet fabrics.

Practical Considerations for Durability and Maintenance

Despite its decorative appearance, burnout velvet fabric can perform reliably when matched to the correct application. Durability depends on fiber selection, pile density, and the proportion of sheer areas. For interiors with moderate use, such as curtains or wall panels, the fabric maintains appearance with minimal maintenance.

| Application | Recommended Fiber Type | Maintenance Focus |

| Window Treatments | Polyester or Polyester Blends | Dust removal and light vacuuming |

| Fashion Garments | Rayon or Silk Blends | Gentle hand wash or dry clean |

| Decorative Panels | Mixed Fiber Blends | Periodic surface cleaning |

Why Burnout Velvet Remains Relevant Across Design Fields

Burnout velvet fabric continues to stand out because it bridges decorative appeal with functional versatility. Its ability to combine opacity and transparency within a single textile makes it adaptable to evolving design requirements in both interiors and apparel. Rather than relying on trends alone, the fabric offers practical solutions for visual layering, light control, and pattern integration.

For designers and manufacturers seeking material differentiation without excessive complexity, burnout velvet provides a balanced approach that supports creativity while maintaining consistent performance across applications.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post