Content

- 1 What is Satin Fabric

- 2 How Satin Fabric is Made

- 3 What Materials Can Satin Be Made From

- 4 Silk vs Satin: Understanding the Difference

- 5 What Satin Fabric Looks and Feels Like

- 6 Popular Types and Variations of Satin Fabric

- 7 Satin Finish in Non-Fabric Contexts

- 8 Common Uses for Satin Fabric

- 9 Caring for Satin Fabric

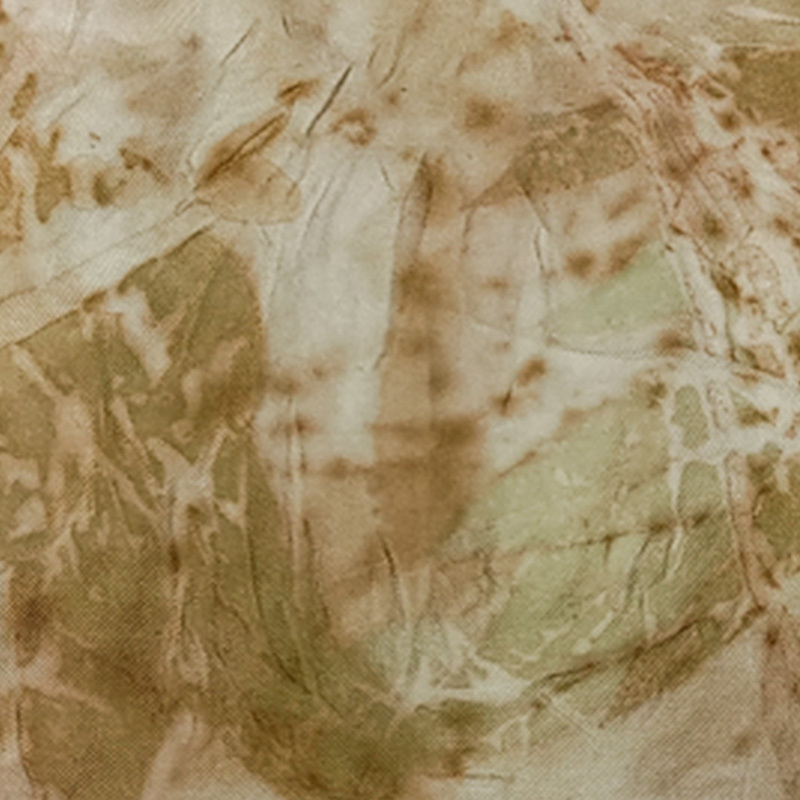

What is Satin Fabric

Satin is not a specific type of fiber or material, but rather a weaving technique that creates a distinctive glossy, smooth surface on fabric. The satin weave produces a lustrous front side and a dull back side, characterized by its silky feel and elegant drape. This luxurious-looking fabric has been prized for centuries in fashion, home décor, and special occasion garments due to its sophisticated appearance and comfortable texture.

The defining characteristic of satin fabric is its unique weave structure, where warp yarns float over multiple weft yarns before going under one. This creates long floats on the surface that reflect light beautifully, giving satin its signature sheen. The fabric can be made from various fibers including silk, polyester, nylon, rayon, or cotton, which means satin fabrics can vary significantly in quality, price, and performance depending on the base material used.

How Satin Fabric is Made

Satin fabric is created using a specific weaving technique called the satin weave, which is one of the three fundamental textile weaves alongside plain weave and twill weave. The satin weave structure requires a minimum of four harnesses on the loom, though more complex satin weaves can use eight or more harnesses for enhanced smoothness and luster.

The Satin Weave Construction

In a satin weave, the warp threads pass over multiple weft threads (typically four to eight) before interlacing under one weft thread. This creates long floats on the fabric surface with minimal interlacing points visible. The pattern distributes these interlacing points evenly across the fabric to avoid creating diagonal lines that would appear in twill weaves. This construction method produces a smooth, continuous surface that reflects light uniformly, creating the characteristic satin shine.

Manufacturing Process

The manufacturing process begins with selecting and preparing the yarn, which may undergo treatments like mercerization for cotton or degumming for silk to enhance luster. The yarns are then loaded onto a loom configured for satin weave. During weaving, tension is carefully controlled to ensure the floats lie smoothly on the surface. After weaving, the fabric typically undergoes finishing processes such as calendaring, which uses heated rollers to further enhance the glossy surface, or chemical treatments to improve durability and reduce wrinkling.

What Materials Can Satin Be Made From

Satin can be manufactured from various fiber types, each bringing different properties, price points, and performance characteristics to the finished fabric. The choice of fiber significantly impacts the quality, durability, care requirements, and cost of the satin fabric.

| Material | Characteristics | Common Uses |

| Silk | Luxurious, breathable, natural sheen, most expensive | Evening gowns, bridal wear, luxury bedding |

| Polyester | Affordable, durable, wrinkle-resistant, less breathable | Sportswear, linings, affordable formal wear |

| Nylon | Strong, elastic, smooth, resistant to damage | Lingerie, activewear, ribbons |

| Rayon | Silky feel, drapes well, semi-synthetic, breathable | Dresses, blouses, linings |

| Cotton | Breathable, comfortable, less sheen than silk, durable | Bed sheets, casual clothing, upholstery |

Silk vs Satin: Understanding the Difference

One of the most common misconceptions in textiles is confusing silk and satin or assuming they are the same thing. Understanding the fundamental difference between these two terms is essential for making informed fabric choices.

Silk is a Fiber, Satin is a Weave

Silk refers to a natural protein fiber produced by silkworms, specifically the larvae of the Bombyx mori moth. It is one of the oldest and most luxurious natural fibers, known for its strength, luster, and smooth texture. Silk can be woven into many different fabric types including charmeuse, chiffon, organza, crepe, and yes, satin.

Satin, on the other hand, is a weave structure, not a fiber type. Satin can be made from silk fibers, but it can also be made from synthetic fibers like polyester or natural fibers like cotton. When you see "silk satin," this refers to satin fabric made from silk fibers, which is the most luxurious and expensive type of satin. When you see "polyester satin," this is satin fabric made from synthetic polyester fibers, which is more affordable but less breathable.

Key Distinctions

- Silk satin combines the luxury of silk fiber with the glossy appearance of satin weave, creating the highest quality and most expensive satin fabric

- Silk can be woven in patterns other than satin, such as plain weave (habotai) or twill weave, which will not have the characteristic satin sheen

- Not all satin is silk, and affordable satin fabrics are typically made from synthetic fibers that mimic the appearance of silk satin

- Pure silk fabric has natural temperature-regulating properties and breathability regardless of the weave, while synthetic satins may not offer these benefits

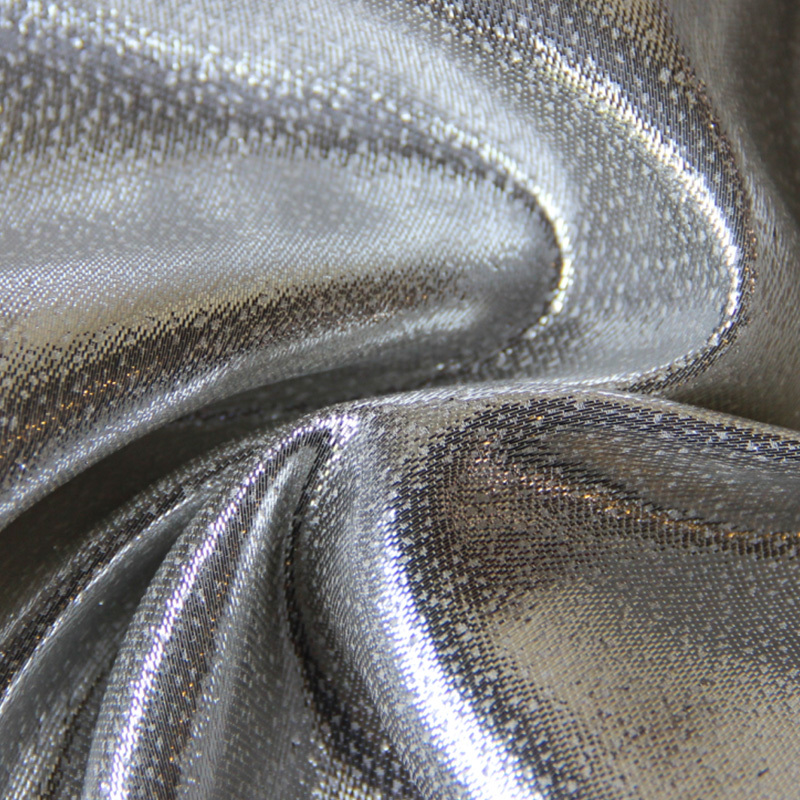

What Satin Fabric Looks and Feels Like

Satin fabric is immediately recognizable by its distinctive appearance and tactile qualities. The visual and sensory characteristics of satin make it a favorite for luxury applications and special occasion garments.

Visual Appearance

The front face of satin fabric displays a lustrous, mirror-like shine that reflects light beautifully. This glossy surface catches and plays with light as the fabric moves, creating an elegant shimmer. The sheen is smooth and continuous rather than sparkly or glittery. In contrast, the back side of satin fabric appears dull and matte, showing the interlacing points where weft threads are visible. The fabric has a fluid, graceful drape that allows it to fall in soft, flowing folds rather than standing stiffly.

Tactile Qualities

When you touch satin fabric, the surface feels incredibly smooth and slippery, almost gliding under your fingers. The fabric is cool to the touch initially, though silk satin will warm to body temperature and regulate heat better than synthetic satins. Satin has a soft, supple hand feel without roughness or texture. The fabric is lightweight to medium-weight depending on the fiber content and thread count, and it flows easily when manipulated. Due to the long floats on the surface, satin can be delicate and prone to snagging, requiring careful handling.

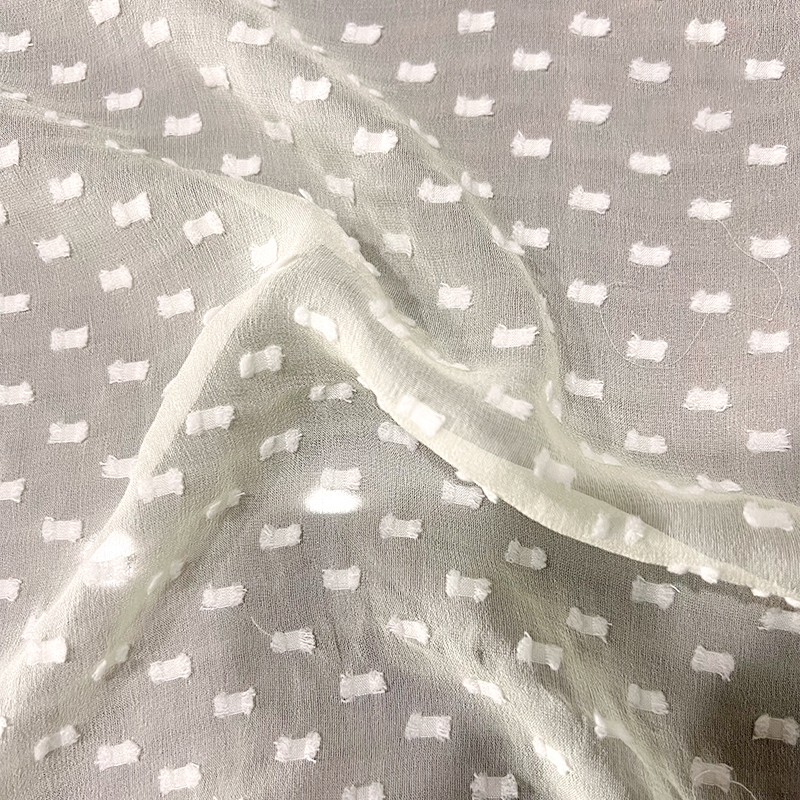

Popular Types and Variations of Satin Fabric

Several variations of satin fabric have been developed for different applications, each with unique characteristics while maintaining the fundamental satin weave structure.

Charmeuse

Charmeuse is a lightweight satin fabric, typically made from silk or polyester, with a moderately lustrous front and a dull crepe-like back. It is softer and has more drape than standard satin, making it ideal for flowing garments like slip dresses, blouses, and lingerie. Charmeuse is one of the most popular types of satin for apparel because it combines elegance with comfort and wearability.

Duchess Satin

Duchess satin is a heavier, stiffer variation with a high luster and substantial body. Originally made from silk, it is now commonly produced in polyester or silk-polyester blends. The fabric has more structure than other satins, making it hold its shape well in structured garments. Duchess satin is the preferred choice for formal gowns, bridal dresses, and evening wear that requires volume and definition.

Crepe-Back Satin

This reversible fabric features a satin weave on one side and a crepe texture on the other, giving designers two distinct looks in one material. The satin side provides the expected glossy finish, while the crepe side offers a matte, slightly textured surface. This versatility allows for creative design possibilities, with garments that can feature both surfaces or be reversible.

Slipper Satin

Slipper satin is a medium to heavyweight satin with a firm texture, originally developed for making ballet slippers and formal shoes. It has a tight weave and substantial body that provides durability while maintaining the characteristic satin sheen. Beyond footwear, slipper satin is used for ribbons, hair accessories, and structured decorative items.

Baronet Satin

Baronet satin, also called baron satin, is made from rayon or cotton using the satin weave. It has a beautiful luster and drape at a more affordable price point than silk satin. This type of satin is commonly used for drapery, upholstery, and costume design where the look of luxury is desired without the high cost of silk.

Satin Finish in Non-Fabric Contexts

The term "satin finish" extends beyond textiles to describe a particular type of surface sheen in various materials and products. Understanding satin finish in these contexts helps clarify why the term is used and how it relates to fabric satin.

In paint, wood finishing, metal polishing, and other surface treatments, a satin finish refers to a semi-gloss appearance that falls between matte (completely non-reflective) and gloss (highly reflective). This finish has a subtle luster that reflects some light while avoiding the mirror-like quality of high-gloss finishes. The name derives from the similarity to satin fabric's characteristic sheen—smooth, elegant, and moderately reflective without being overly shiny or flat.

Satin finish is particularly popular in interior design because it provides visual interest and sophistication while being easier to maintain than high-gloss finishes, which show every imperfection. In jewelry and metalwork, a satin finish creates a soft, brushed appearance that reduces glare while maintaining an upscale look. This versatile finish strikes a balance between elegance and practicality across numerous applications.

Common Uses for Satin Fabric

Satin fabric's combination of beauty, comfort, and drape makes it suitable for a wide range of applications in fashion, home décor, and specialized products.

- Bridal and evening wear, including wedding dresses, bridesmaid gowns, and formal attire where elegance and luxury are essential

- Lingerie and sleepwear, taking advantage of satin's smooth, sensual feel against the skin and its attractive drape

- Luxury bedding including sheets, pillowcases, and duvet covers, particularly silk satin which is valued for hair and skin benefits

- Garment linings for jackets, coats, and suits, where satin's slippery surface allows easy wearing and removal

- Ballet and pointe shoes, using slipper satin for its combination of strength and elegance

- Ribbons, bows, and decorative trim for gift wrapping, crafts, and embellishments

- Upholstery and drapery for formal spaces where a luxurious aesthetic is desired

- Blouses, skirts, and dresses for both casual and formal occasions, offering versatility in design

- Athletic and performance wear, particularly polyester or nylon satin for its smooth finish and moisture-wicking properties

Caring for Satin Fabric

Proper care of satin fabric depends significantly on the fiber content, as silk satin requires very different treatment than polyester or cotton satin. Understanding the specific needs of your satin garments or textiles will help preserve their beauty and extend their lifespan.

Washing and Cleaning

Silk satin typically requires dry cleaning or very gentle hand washing in cool water with mild detergent specifically formulated for silk. The fabric should never be wrung or twisted, but rather rolled in a towel to remove excess water. Polyester and nylon satins are generally more durable and can often be machine washed on a gentle cycle in cool water, though placing them in a mesh laundry bag protects against snagging. Cotton satin can usually tolerate regular machine washing but may benefit from gentle cycles to preserve the finish. Always check the care label on your specific garment, as manufacturers provide guidance based on the exact fabric composition and construction.

Drying and Ironing

Satin fabrics should generally be air-dried away from direct sunlight and heat, as high temperatures can damage the fibers and dull the sheen. If ironing is necessary, use the lowest temperature setting appropriate for the fiber type and always iron on the wrong (dull) side of the fabric, preferably with a pressing cloth between the iron and fabric to prevent shine marks or scorching. Steaming is often a safer alternative to ironing for removing wrinkles from satin garments. For storage, satin items should be hung or folded carefully to avoid creasing, and kept away from rough surfaces that could snag the delicate surface floats.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post