How do sustainable fabrics compare in durability and comfort to traditional textiles?

Content

- 1 Material Composition and Structural Differences

- 2 Durability Testing and Wear Resistance

- 3 Comfort: Breathability, Moisture Management, and Thermal Regulation

- 4 Maintenance, Longevity, and Performance Stability

- 5 Comparative Overview of Key Performance Attributes

- 6 Practical Insights for Industry and Consumers

Material Composition and Structural Differences

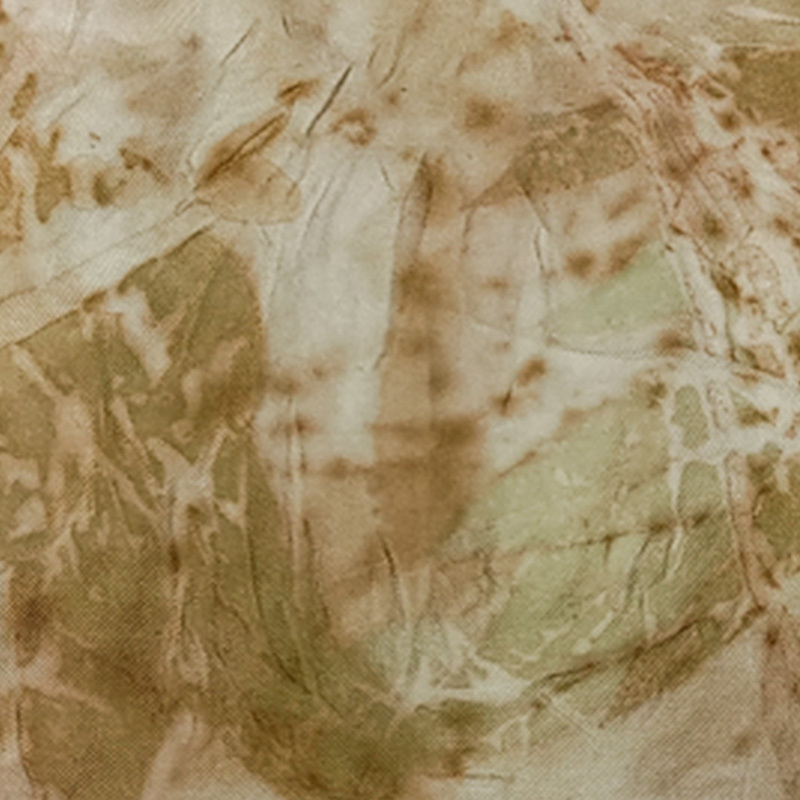

The durability and comfort of sustainable fabrics are influenced by their fiber composition and structural properties. Natural fibers such as organic cotton, hemp, and linen possess high tensile strength and a stable molecular structure that enhances longevity. Regenerated fibers like Tencel and bamboo viscose are engineered to provide smooth texture and high moisture absorption, improving comfort while maintaining moderate durability. In comparison, traditional textiles such as polyester and nylon rely on synthetic polymers that offer high abrasion resistance but may compromise breathability and tactile softness.

The spinning and weaving techniques used in sustainable fabrics often emphasize tighter construction with fewer chemical coatings, contributing to balanced strength and natural feel. These production choices create a structure that resists wear while maintaining airflow and softness — key indicators of both comfort and lasting quality.

Durability Testing and Wear Resistance

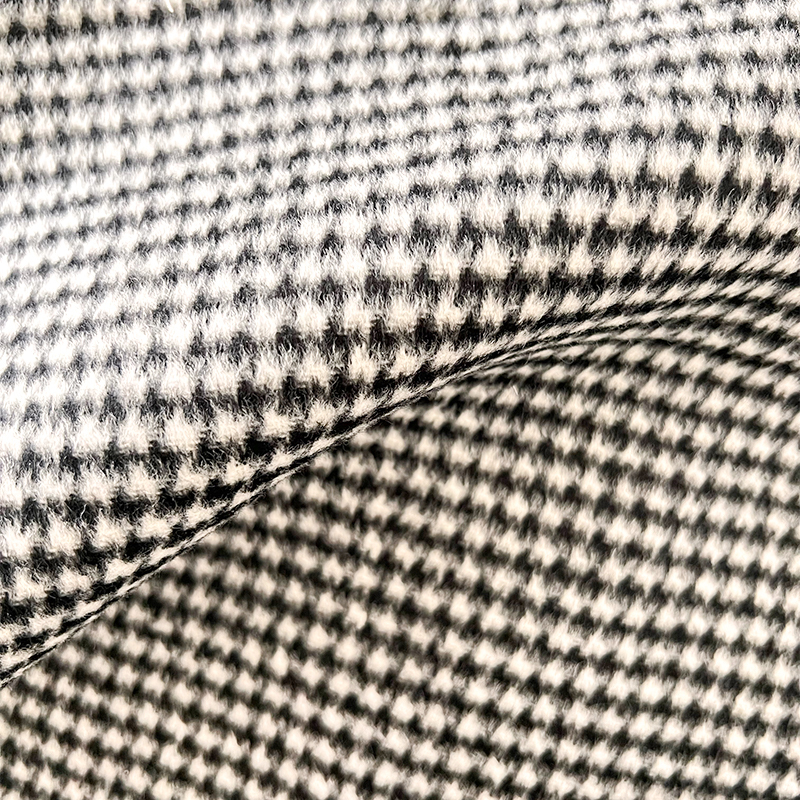

Durability assessment for sustainable fabrics focuses on abrasion resistance, tear strength, and dimensional stability after multiple washing cycles. Tests such as ASTM D4966 for abrasion and ISO 6330 for washing performance are often applied to evaluate endurance. While traditional synthetics tend to excel in friction and pilling resistance, advanced sustainable options such as hemp blends and recycled polyester now show comparable outcomes.

The fiber’s internal bonding and surface finish play a significant role. Hemp and linen fibers, for instance, develop higher structural rigidity over time, making them suitable for long-term applications like upholstery and workwear. Recycled polyester also contributes to sustainability without compromising lifespan, as it retains most of the mechanical properties of virgin fibers while reducing environmental footprint.

Comfort: Breathability, Moisture Management, and Thermal Regulation

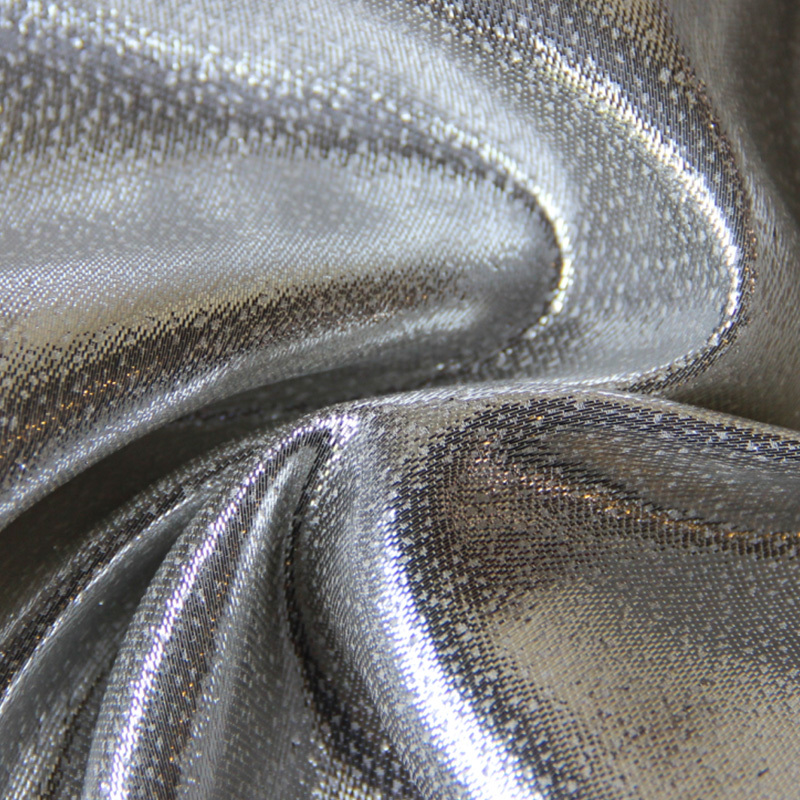

Comfort in sustainable fabrics is largely determined by air permeability, thermal balance, and moisture control. Natural fibers such as organic cotton and bamboo viscose exhibit excellent wicking performance, allowing the fabric to draw moisture away from the skin. This enhances comfort in both warm and humid environments. Traditional textiles like polyester may trap heat and moisture unless specially treated with hydrophilic finishes.

The smooth fiber surfaces of sustainable materials like Tencel reduce skin friction and irritation, improving wearability for sensitive users. Additionally, these fabrics regulate body temperature by allowing better heat dissipation. This combination of breathability and softness provides a tactile advantage over conventional synthetics that depend heavily on chemical softeners.

Maintenance, Longevity, and Performance Stability

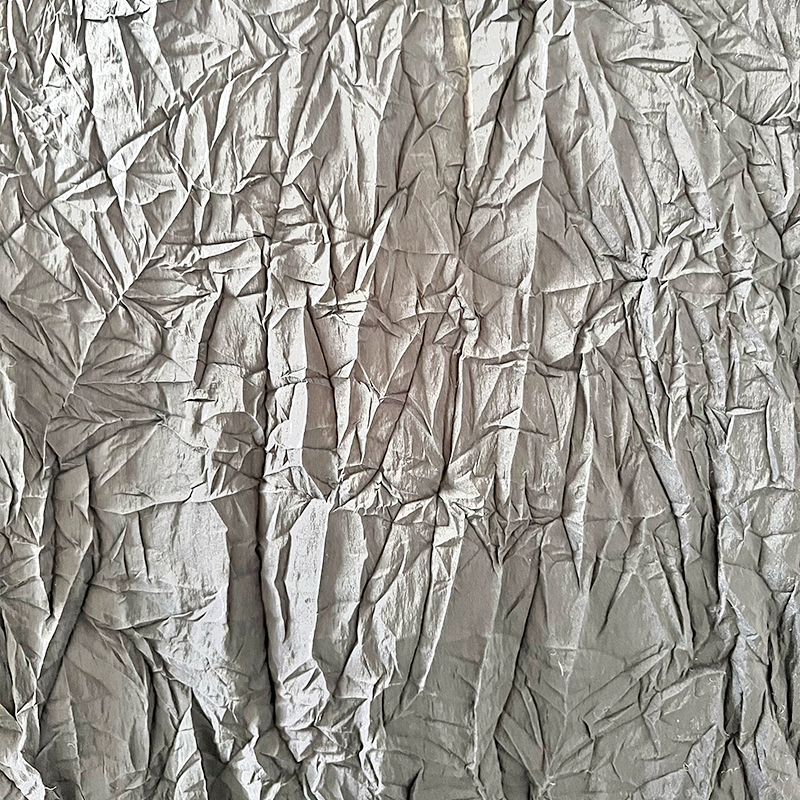

A critical aspect of comparing sustainable and traditional textiles lies in maintenance requirements and performance over time. Sustainable fabrics typically require gentler washing conditions and avoid high-temperature drying to preserve fiber integrity. Despite these considerations, many retain their shape and texture for extended periods, particularly hemp-cotton or recycled polyester blends. Traditional textiles may withstand harsher conditions but often degrade in hand feel due to repeated exposure to detergents and heat.

Lifecycle analyses have shown that durable sustainable fabrics contribute to lower overall environmental impact since fewer replacements are needed over time. By optimizing fiber processing and fabric finishing, manufacturers can balance resilience and comfort without relying on excessive chemical reinforcement.

Comparative Overview of Key Performance Attributes

| Fabric Type | Durability | Comfort | Environmental Impact |

| Organic Cotton | Moderate to High | High (soft, breathable) | Low |

| Hemp | High | Moderate (firmer texture) | Very Low |

| Tencel (Lyocell) | Moderate | High (smooth, cooling) | Low |

| Conventional Polyester | Very High | Moderate (less breathable) | High |

Practical Insights for Industry and Consumers

For manufacturers, the balance between durability and comfort in sustainable fabrics is achieved through material blending and eco-conscious finishing. Combining organic cotton with recycled polyester, for example, can produce a fabric that maintains resilience while offering superior softness and lower environmental impact. For consumers, fabric selection depends on intended use — hemp for rugged applications, Tencel for premium comfort, and organic cotton for everyday wear.

Ultimately, sustainable fabrics are no longer limited to niche applications. Advances in fiber technology and green chemistry now allow them to compete directly with traditional textiles, achieving both mechanical strength and comfort while supporting long-term environmental responsibility.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post