What types of natural and synthetic fibers are most commonly used in sustainable fabrics today?

Content

- 1 Natural fibers commonly used in sustainable textiles

- 2 Regenerated and bio-based cellulosic fibers

- 3 Synthetic and recycled synthetic fibers

- 4 Blends, composites and design-for-recycling implications

- 5 Comparative table: common fibers, sustainability highlights and typical uses

- 6 Standards, certifications and traceability to verify sustainability

- 7 Procurement checklist for choosing fibers

- 8 Conclusion — practical guidance for designers and specifiers

Natural fibers commonly used in sustainable textiles

Natural fibers remain a cornerstone of sustainable textiles when sourced and processed responsibly. Below are the most common natural fibers used today and why they are selected for sustainability-led products.

Organic cotton

Organic cotton is grown without synthetic pesticides or genetically modified seed and typically uses crop-rotation practices that improve soil health. Compared with conventional cotton, organic cotton reduces chemical inputs and often uses less irrigation depending on region. Common applications: T-shirts, denim, casual apparel and home textiles.

Hemp and flax (linen)

Hemp and flax are low-input bast fibers that require little fertilizer or irrigation and produce high yields per hectare. They have excellent mechanical strength, biodegradability and a low pesticide profile. These fibers are popular for apparel, workwear, upholstery and technical textiles where durability matters.

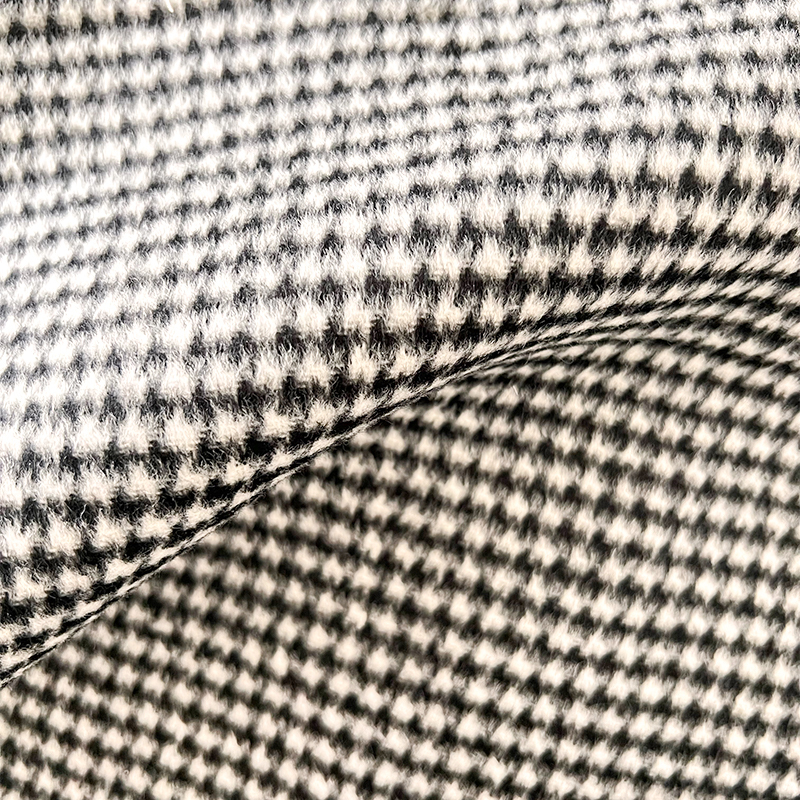

Wool (responsibly sourced)

Wool is renewable, biodegradable and provides natural flame resistance and thermal regulation. Sustainability depends on animal welfare (mulesing-free), pasture management, and supply-chain traceability. Wool is widely used in knitwear, suiting, insulation and technical acoustic/thermal applications.

Silk and alternative silks

Traditional silk is a high-performing natural fiber but can have animal-welfare and energy concerns. Alternatives such as peace silk (non-violent sericulture) or lab-grown silk proteins are emerging for higher sustainability credentials. Silk is used in luxury apparel and performance fabrics where lightweight strength is needed.

Less common but growing: jute, ramie, nettle, kapok

These fibers offer niche sustainability benefits — low-input farming, biodegradability and regional availability. Jute and ramie are used in industrial textiles and home goods; kapok is used for lightweight insulation and fillers.

Regenerated and bio-based cellulosic fibers

Regenerated cellulosic fibers transform cellulose from wood or agricultural residues into fibers. They bridge natural and synthetic worlds by delivering high performance with improved resource efficiency when produced in closed-loop systems.

Lyocell (Tencel) and Modal

Lyocell and modal are produced using solvent-spinning processes that can be closed-loop, recovering the solvent and drastically reducing effluent. Lyocell excels in strength, moisture wicking and biodegradability; modal is softer and used in premium knitwear and underwear.

Viscose / rayon (with improved practices)

Viscose historically posed environmental issues due to chemical use and deforestation risk. When sourced from certified sustainably managed forests and produced in modern closed-loop mills, viscose can be part of sustainable portfolios — though lyocell is generally preferred where available.

Synthetic and recycled synthetic fibers

Synthetics historically score poorly on biodegradability but can deliver sustainability gains when made from recycled feedstocks or bio-based monomers. Durable performance and recycling infrastructure make some synthetics attractive for circular systems.

Recycled polyester (rPET)

rPET is produced from post-consumer PET bottles or industrial polyester waste. It reduces dependence on virgin petroleum feedstock and cuts energy and carbon per kilogram compared with virgin polyester. Challenges include microplastic shedding and ensuring traceable recycled content.

Recycled nylon and regenerated polyamides

Recycled nylon (from fishing nets, carpet waste) reduces landfill and marine pollution. Regenerated polyamides can achieve near-equal mechanical performance to virgin nylon, making them suitable for activewear, outerwear and industrial textiles.

Bio-based polymers (PLA and others)

Polylactic acid (PLA) and emerging bio-based polyesters offer renewable feedstocks. PLA is compostable under industrial conditions but has lower high-temperature performance; it is used for nonwoven applications and certain knit fabrics. Ongoing research aims to improve performance and recyclability of bio-polymers.

Blends, composites and design-for-recycling implications

Blending fibers combines properties but complicates recycling. For circularity, single-fiber streams or mechanically separable constructions are preferable. Where blends are necessary (e.g., cotton–polyester for comfort and durability), design choices should prioritize high recycled content, clear labeling and take-back or chemical-recycling options.

Comparative table: common fibers, sustainability highlights and typical uses

| Fiber | Sustainability highlights | Common applications |

| Organic cotton | Reduced pesticides, soil health | Apparel, denim, home textiles |

| Hemp / flax | Low inputs, high yield, durable | Workwear, upholstery, technical textiles |

| Lyocell (Tencel) | Closed-loop solvent process, biodegradable | Knitwear, bedding, performance wear |

| Recycled polyester (rPET) | Uses post-consumer waste, lower carbon than virgin | Outdoor wear, activewear, linings |

| Wool (certified) | Renewable, biodegradable, durable | Knitwear, insulation, technical textiles |

Standards, certifications and traceability to verify sustainability

Use recognized certifications to validate claims: GOTS for organic fibers, FSC/PEFC for responsibly sourced wood pulp (cellulosics), OEKO-TEX for harmful substances, Global Recycled Standard (GRS) for recycled content, and RCS for recycled claims. Ask suppliers for chain-of-custody documentation and third-party test reports when R-values, durability or recycled content are critical.

Procurement checklist for choosing fibers

- Define functional needs (durability, stretch, drape, flame resistance) before choosing fiber — performance often drives material choice.

- Prioritize closed-loop or recycled feedstocks where possible (lyocell, rPET, recycled nylon).

- Specify certifications (GOTS, GRS, OEKO-TEX) and require supplier transparency for origin and processing.

- Design for end-of-life: choose mono-fiber constructions or document recycling pathways for blends.

Conclusion — practical guidance for designers and specifiers

The most commonly used fibers in sustainable fabrics today include responsibly sourced natural fibers (organic cotton, hemp, flax, certified wool), regenerated cellulosics (lyocell, modal) and recycled synthetics (rPET, recycled nylon). The best choice depends on the specific product requirements, local supply-chain realities and verified sustainability credentials. Prioritize fibers with documented lower resource intensity, closed-loop processing, and clear end-of-life options to maximize the environmental benefits of your textile products.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post